The journey from raw spirulina production to globally acceptable nutraceutical blends is not linear. It demands more than cultivation success – it requires foresight in design, process discipline, and the ability to scale without disrupting quality. The Virdinia project in Tamil Nadu represents a new generation of spirulina ventures that approach growth strategically, not incrementally.

This article explores how three young entrepreneurs from the textile sector built an export-oriented spirulina blending operation by combining smart infrastructure planning with phased scale-up – supported closely by Greenbubble.

Project Background: From Textiles to Nutraceuticals

Virdinia was founded by three young entrepreneurs with roots in the textile industry – an environment where consistency, batch control, and process repeatability are non-negotiable. Their entry into spirulina farming was driven by an ambition to move beyond commodity powder and into value-added, exportable spirulina blends.

The project began as a 1.5-acre pilot facility in Tamil Nadu, with a clearly defined roadmap to expand into a 10-acre commercial operation. Unlike many first-time agripreneurs, the founders treated the pilot not as an experiment, but as a validation phase for infrastructure, compliance, and scalability.

Early Course Correction: Why Design Came Before Construction

Before construction began, the Virdinia team reassessed their initial approach after realising that their first consulting partner lacked the domain depth required for export-oriented spirulina projects. This early pause proved decisive.

Greenbubble was brought in at a stage where no irreversible construction had taken place. This allowed the entire business plan, site layout, and process flow to be redesigned from scratch – without the constraints of legacy decisions.

Reframing Spirulina as a Blending-Led Business

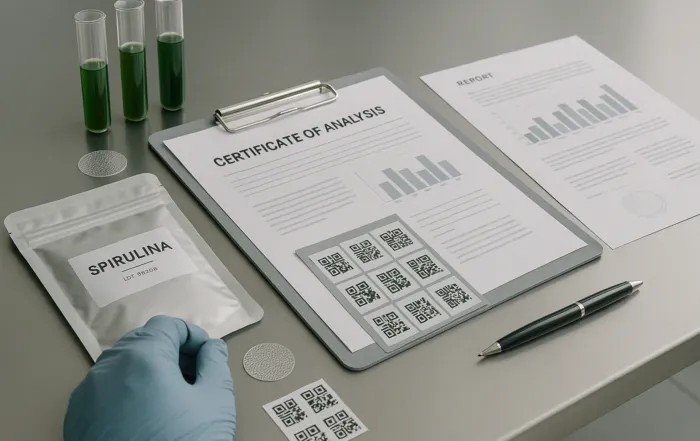

Unlike farms focused solely on bulk powder, Virdinia’s core differentiation lies in spirulina blends designed for specific functional outcomes. Exportable blends demand tighter control over:

- Ingredient segregation

- Batch traceability

- Hygienic handling between components

- Repeatable formulation accuracy

This shift fundamentally changed how infrastructure was planned. Blending was treated as a central operation, not an add-on.

Scalable Infrastructure: Designing for 10 Acres from Day One

One of the defining features of the Virdinia project is its scalability-first design philosophy. While the initial operation covered only 1.5 acres, plumbing layouts, processing zones, and utility corridors were designed to support a future 10-acre footprint.

Greenbubble ensured that:

- Core pipelines did not require rerouting during expansion

- Processing and blending zones could scale linearly

- Utility loads were future-proofed

- Expansion would not disrupt ongoing production

This approach played a critical role in securing bank funding, as it demonstrated technical foresight and controlled growth risk.

Integration of Farming, Processing, and Blending

Exportable spirulina blends demand consistency across stages. Variability introduced during cultivation or handling amplifies during blending.

To reduce this risk, Greenbubble aligned upstream systems – including engineered raceway pond systems and controlled harvesting equipment – with downstream processing logic. This ensured that raw spirulina entering the blending pipeline met predictable quality benchmarks.

Learning from Consumer-Facing Nutraceuticals

While Virdinia operates as a manufacturing venture, its approach to blends has been shaped by real-world nutraceutical brand requirements rather than theoretical formulations. A key milestone for the project has been supplying spirulina inputs for consumer-facing wellness brands where consistency, taste masking, and batch repeatability are non-negotiable.

One such example is Virdinia’s association with Cosmix, a modern wellness brand known for its functional spirulina blends. Products like Cosmix’s Blue Blend place strict expectations on colour stability, micronutrient balance, and sensory neutrality – benchmarks that directly influence how upstream spirulina is cultivated, handled, and blended.

This downstream demand reinforced Virdinia’s focus on blend-led infrastructure, where spirulina is produced and handled to meet the repeatability, sensory consistency, and quality discipline required for formulations such as Cosmix’s Bring Me Bliss blend.

This market awareness shaped decisions around blending hygiene, batch sizing, traceability, and packaging readiness.

Greenbubble’s Role in De-Risking Scale and Investment

Greenbubble’s involvement extended beyond technical consulting. By redesigning layouts, aligning scale-up strategy, and validating infrastructure logic, Greenbubble helped Virdinia reduce execution risk at a stage where errors are typically most expensive.

The result was a pilot facility that functioned not as a small farm, but as a scaled-down version of the final 10-acre operation – making expansion a matter of replication rather than reinvention.

Current Status: From Pilot Success to Active Expansion

Following the success of the pilot phase, Virdinia is now actively expanding toward its planned 10-acre facility with Greenbubble’s continued involvement. The early design discipline has allowed this transition to proceed without major structural changes or operational downtime.

This continuity is rare in first-generation spirulina ventures and underscores the value of starting with scale in mind.

What Emerging Spirulina Brands Can Learn

The Virdinia project offers several lessons for entrepreneurs entering the microalgae sector:

- Pilot farms should validate scalability, not just yield

- Infrastructure must anticipate blending and formulation needs

- Early design corrections save long-term capital

- Smart layouts improve fundability and execution confidence

Export success is built into the farm – not added later.

FAQs

Q1. Why did Virdinia start with a pilot instead of full scale?

The pilot phase was used to validate infrastructure logic, process stability, and scalability before committing to full-scale investment.

Q2. How did scalable design help with bank funding?

Future-ready layouts reduced expansion risk, making the project more attractive to lenders.

Q3. Are spirulina blends harder to export than plain powder?

Yes. Blends require tighter quality control, traceability, and repeatability.

Q4. Can small farms plan for blends from the beginning?

Yes, but it requires intentional design and process discipline from day one.

Q5. Is Greenbubble still involved in the Virdinia project?

Yes. Greenbubble continues to support the project during its expansion phase.

Conclusion: Scaling Spirulina Is a Design Decision

The Virdinia project demonstrates that exportable spirulina blends are not a function of scale alone, but of design intent. By treating the pilot phase as a foundation for long-term growth – and by integrating smart infrastructure planning early – Virdinia has positioned itself as a next-generation spirulina venture. With Greenbubble’s continued involvement, the project highlights how thoughtful design can turn ambition into scalable reality.