The drying process is one of the most crucial steps in spirulina farming and significantly determines the final product’s quality, shelf life, and nutritional value. Whether you’re an organic-certified producer or a bulk supplier, the dryer you choose impacts consumer trust, certification eligibility, and long-term profitability. This guide offers a detailed comparison of three leading spirulina drying methods: Refractive Window Drying (RWD), Vacuum Drying, and Spray Drying. We explore how each method works, their pros and cons, costs involved, and which type is most suitable for different farm setups.

Why the Right Dryer Matters in Spirulina Farming

Spirulina is known for its rich concentration of nutrients, including proteins, vitamins, pigments, and antioxidants. However, these compounds are highly sensitive to temperature, oxidation, and UV light. Choosing the wrong dryer can result in a nutrient-depleted product that fails quality tests and certification audits.

Here’s what poor drying can destroy:

- Phycocyanin: The blue pigment unique to spirulina, responsible for antioxidant benefits

- Beta-carotene: A precursor to Vitamin A, important for immunity and vision

- Essential amino acids: Crucial for protein synthesis

- Vitamin B complex: Vital for metabolism and energy release

Additionally, a compromised drying process can lead to off-flavors, reduced solubility, and an undesirable dark green color—all of which lower market appeal.

For producers targeting organic, nutraceutical, or export-grade spirulina, using the right dryer is non-negotiable.

Overview of Common Spirulina Drying Techniques

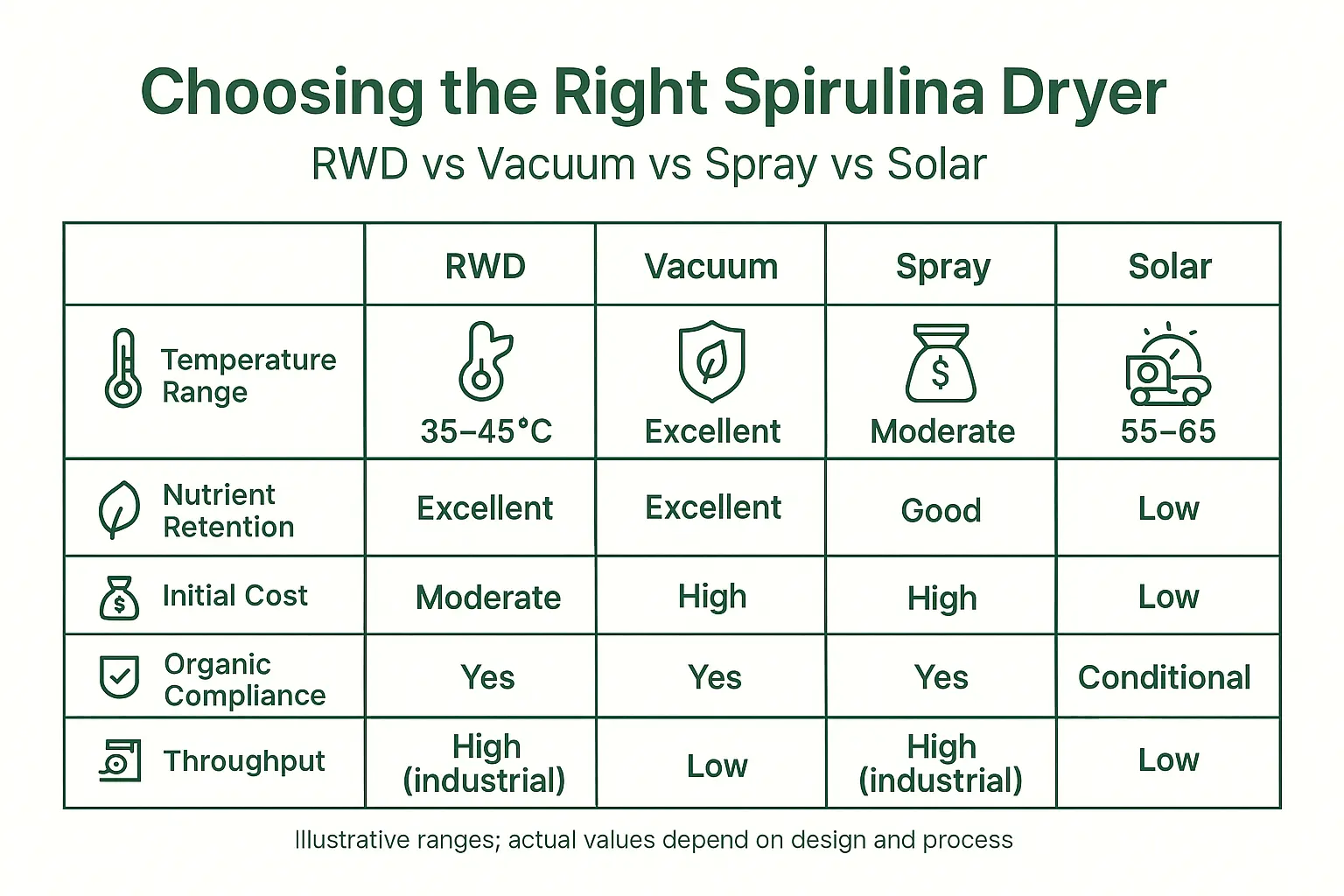

| Drying Method | Temperature Range | Nutrient Retention | Initial Cost | Organic Compliance | Throughput |

| Refractive Window (RWD) | 35–45°C | Excellent | Moderate | Yes | High (Industrial) |

| Vacuum Drying | 40–50°C | Very Good | High | Yes | Medium |

| Spray Drying | 100–180°C | Good | High | Yes | High (Industrial) |

| Solar Drying | 55 – 65 | Low | Low | Conditional | Low |

Refractive Window Drying (RWD)

RWD uses refracted light and gentle infrared heat to remove moisture from spirulina at low temperatures. A transparent drying surface allows light to penetrate and evaporate water from the biomass, while a reflective panel accelerates drying without direct heating.

How It Works:

- Biomass is spread as a thin film on a transparent surface

- Light and gentle infrared heat evaporate water

- Moisture is released without heating above 45°C

Advantages:

- Retains 90%+ of nutrients, especially phycocyanin and beta-carotene

- Minimal oxidation and color change

- Certified by most organic inspection agencies

- Compact design suitable for small to large-scale farms

Limitations:

- Lower throughput per cycle compared to spray dryers

- Slightly higher initial investment than traditional solar dryers

- Needs stable indoor or semi-shaded drying environment

Vacuum Drying

Vacuum drying involves placing spirulina biomass in a sealed chamber where air pressure is reduced, allowing moisture to evaporate at lower temperatures. Because oxygen is removed, nutrient degradation and microbial contamination risks are significantly reduced.

How It Works:

- Biomass is loaded into trays within a vacuum chamber

- Heat is applied indirectly through conductive plates

- Water evaporates under reduced pressure

Advantages:

- Excellent for retaining amino acids and pigments

- Prevents oxidation and mold growth

- Meets HACCP and GMP protocols for export

- Supports traceability with batch-controlled systems

Limitations:

- High energy usage

- Slower drying time (4–6 hours per batch)

- Requires trained staff for maintenance

- Higher labour requirements

- High capital cost

See how it supports spirulina quality control

Spray Drying

Spray drying involves atomizing spirulina slurry into fine droplets and spraying it into a heated chamber where moisture evaporates instantly.

How It Works:

- Liquid spirulina is pumped through a nozzle to create micro-droplets

- Droplets are exposed to heated air (100–180°C)

- Powder is collected at the bottom of the chamber

Advantages:

- Extremely fast (minutes per batch)

- Low labour cost

- Can be scaled for industrial volumes

Limitations:

- Destroys heat-sensitive nutrients, especially phycocyanin

- Results in coarse, dull powder with poor water solubility

- High operational cost requiring high energy and fuel

- High maintenance cost with multiple servicing required over its life time

- Lacks flavor and aroma

Note: Spray drying is not recommended for premium-grade or organic spirulina production.

Which Dryer Should You Choose?

If You’re Targeting:

- USDA/EU Organic Certification: Choose RWD or Vacuum Drying

- Nutritional Spirulina for Export: RWD drying is ideal

- Local Market or Capsule Manufacturing: RWD balances cost and quality

- Bulk Non-Human Use (e.g., Animal Feed): Solar drying

- Small scale farm: Vacuum drying for small batch sizes

Your dryer should match your product goals. Choosing incorrectly can limit your access to high-paying export markets and prevent certification.

Cost Comparison Snapshot

For a complete overview of costs beyond drying equipment, including setup, labor, and certification, check out our insights on overall spirulina farming costs and ROI.

| Dryer Type | CapEx Range (INR) | Operational Cost | Labor Requirement | Market Focus |

| RWD | ₹10–12 Lakhs | Medium | Low | Organic retail, D2C brands, exports and industrial nutraceuticals |

| Vacuum Dryer | ₹15–20 Lakhs | High | Skilled | Small farms |

| Spray Dryer | ₹6–8 Lakhs | Low | Low |

Keep in mind that operational cost includes electricity, cleaning cycles, maintenance, and training.

Energy Efficiency & Sustainability

Modern drying systems can also be integrated into smart automation networks. Learn more about automating the drying and harvesting process to improve efficiency, reduce manual errors, and comply with certification standards.

For sustainable spirulina farms, RWD and vacuum drying are far more environmentally friendly compared to spray drying. Spray dryers consume more power due to their high-heat output. If you’re applying for green farming subsidies or certifications like Carbon-Neutral Farming, low-temperature dryers will help you qualify.

Conclusion: Match Your Dryer to Your Market

The drying system you invest in is a long-term decision that determines the quality, pricing, and reach of your spirulina product. For farms looking to scale organically, preserve premium nutritional value, and export to high-paying markets, Refractive Window Dryers or Vacuum Dryers are the best fit. They comply with organic regulations and maintain the integrity of bioactive compounds.

On the other hand, if your priority is high throughput for bulk applications where nutrient density isn’t critical, Spray Dryers offer speed and affordability, albeit with quality trade-offs.

Need help configuring your spirulina drying system? Explore our complete range of drying equipment solutions or contact our team for tailored recommendations based on your farm size, budget, and compliance goals.