Spirulina farming is often marketed online as a high-margin, quick-return agricultural business. Claims of earning massive profits from a single acre with minimal investment are common-but rarely accurate. In reality, spirulina farming profit per acre depends on scale, automation, certification readiness, quality control, and market access. When these factors are ignored, especially in small manual farms, profitability quickly collapses.

In this article, I break down the real economics of spirulina farming per acre, explain why many 1-acre farms fail to generate sustainable profits, and outline how serious producers maximize returns through scale, automation, and export-grade compliance-an approach consistently seen in professionally engineered spirulina farms designed by experienced solution providers like Greenbubble.

Understanding Profit Per Acre in Spirulina Farming

Profit per acre is not just a function of yield. It is the result of a complex balance between capital expenditure (CapEx), operating expenditure (OpEx), market pricing, and the ability to maintain consistent quality without contamination or certification failures.

Spirulina is a high-input crop. It requires controlled alkalinity, continuous carbon supply, precise temperature management, regular harvesting, low-temperature drying, and rigorous testing. These requirements create a cost structure that small, manual farms cannot absorb efficiently.

Why High Profit per Acre Claims Are Misleading

Many online sources claim that even a single acre of spirulina farming can generate exceptional profits within months. These claims usually rely on three flawed assumptions:

- Manual operations are sufficient for commercial-scale consistency

- Operating costs are negligible or temporary

- Certification and quality compliance are optional

In reality, manual farms face higher labor costs, inconsistent output, contamination risks, and near-zero export eligibility. Without automation and quality infrastructure, profits remain unstable or negative.

Capital Investment Required Per Acre

A commercial-grade spirulina farm designed for profitability requires far more than just ponds. Below is a realistic investment range for a 1-acre automated spirulina farm.

| Component | Estimated Cost (INR) |

| Pond construction & civil work | ₹15–18 Lakhs |

| Agitation systems | ₹5–8 Lakhs |

| Harvesting & dewatering equipment | ₹10–12 Lakhs |

| Drying system (RWD / Vacuum) | ₹10–18 Lakhs |

| Packaging & cleanroom | ₹6–8 Lakhs |

| Automation (IoT / SCADA) | ₹3–5 Lakhs |

| In-house lab & QC | ₹10–12 Lakhs |

| Certification & documentation | ₹4–6 Lakhs |

| Total Investment | ₹73–107 Lakhs |

This level of investment is essential for maintaining consistent quality, reducing human contact, and passing GMP, HACCP, and organic audits.

For farms seeking faster deployment and technical assurance, turnkey implementation models such as Greenbubble’s spirulina farming turnkey solutions significantly reduce execution risks by integrating equipment, automation, and compliance from day one. This systems-driven approach is commonly adopted by large-scale projects executed under the Greenbubble framework, where engineering, process control, and certification readiness are planned together.

Operating Costs That Impact Profit Per Acre

Even after setup, spirulina farms incur substantial annual operating expenses. Nutrients, testing, labor, power, and certifications form the bulk of recurring costs.

For a 1-acre farm, typical annual operating costs include:

| Expense Category | Annual Cost (INR) |

| Power & utilities | ₹6–7 Lakhs |

| Nutrients & carbon sources | ₹18–28 Lakhs |

| Testing & chemicals | ₹2–3 Lakhs |

| Salaries & skilled labor | ₹15–18 Lakhs |

| Packing & consumables | ₹3–4 Lakhs |

| Miscellaneous & maintenance | ₹5 Lakhs |

| Total OpEx | ~₹53–60 Lakhs |

These costs are unavoidable if quality, yield, and certification stability are to be maintained.

The Reality of 1-Acre Spirulina Farming Profit

When realistic costs are considered, most 1-acre spirulina farms struggle to achieve profitability.

| Metric | 1 Acre Farm |

| Average Revenue | ₹70–75 Lakhs |

| Total Operating Cost | ₹80–85 Lakhs |

| Net Profit / Loss | -₹5 to -₹10 Lakhs |

| ROI | Negative |

This is why many single-acre farms either shut down, downgrade quality, or pivot to training/demo operations rather than commercial supply. A deeper ROI breakdown is covered in Spirulina farming profitable in 2025.

Why Scale Changes Everything

Profitability in spirulina farming improves dramatically with scale. At 2–3 acres, fixed costs such as lab setup, certifications, management, and automation are distributed across higher production volumes.

| Metric | 3 Acre Farm |

| Capital Investment | ₹1.8–2.5 Crore |

| Average Revenue | ₹1.9–2.1 Crore |

| Operating Cost | ₹1.2–1.3 Crore |

| Net Profit | ₹70–80 Lakhs |

| ROI | ~35–40% |

This is the minimum scale at which spirulina farming becomes commercially sustainable and export-ready.

Role of Automation in Maximizing Profit Per Acre

Automation directly impacts profitability by reducing labor dependency, improving yield consistency, and preventing contamination.

Key automation systems include (often delivered through structuredGreenbubble’s spirulina farming consultancy models):

- Automated agitators to control temperature and oxygen levels

- Sensor-based pH, temperature, and salinity monitoring

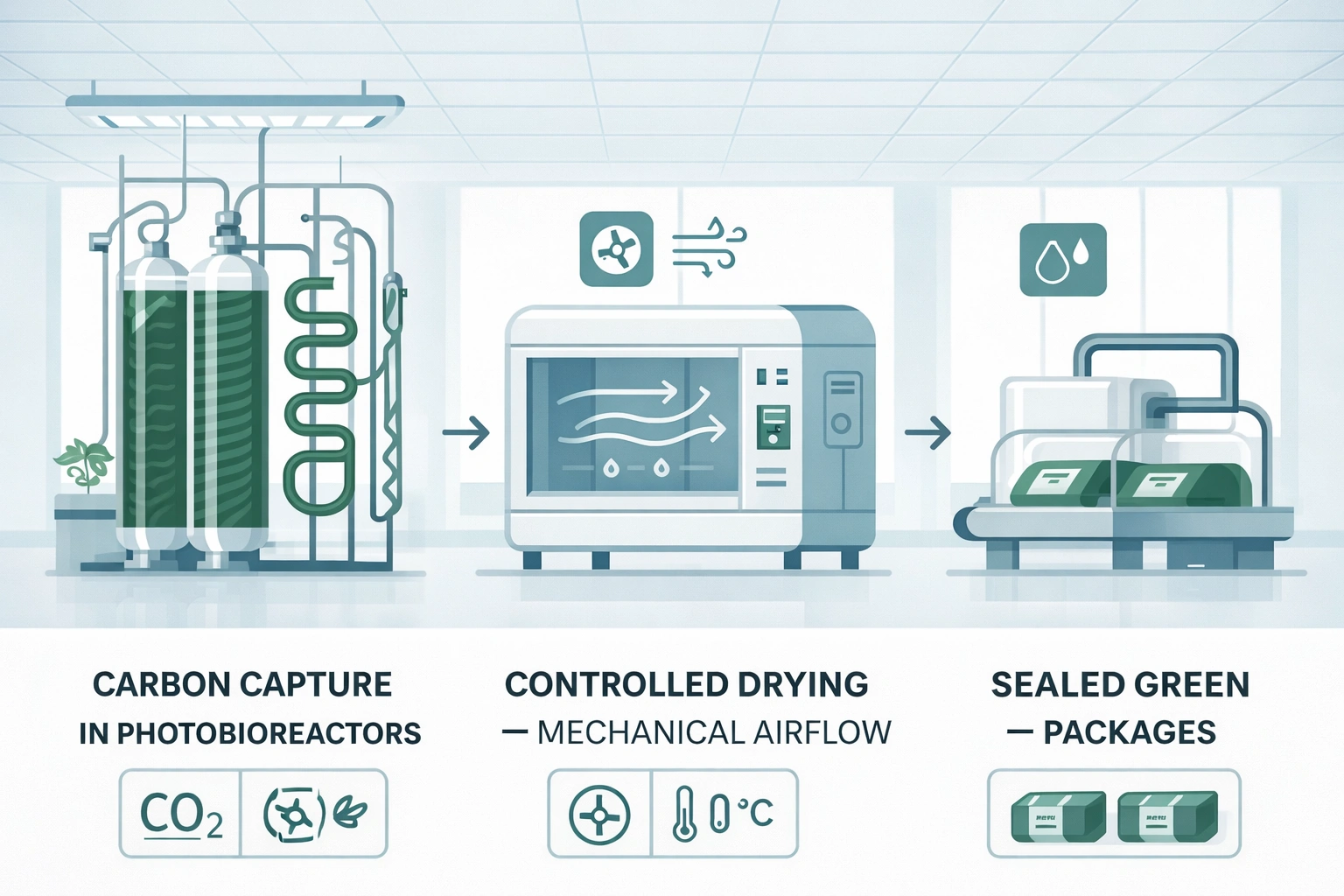

- Automated harvesting and dewatering systems

- Low-temperature drying systems

- Automated packing systems

Investments in Greenbubble’s harvesting equipment, Greenbubble’s efficient agitators, and Greenbubble’s RWD drying systems are critical to maintaining nutrient integrity and reducing rejection rates.

Manual harvesting and drying significantly increase contamination risk and operational inconsistency, making certification audits difficult to pass.

Drying Technology and Profit Retention

Drying is one of the most profit-critical stages in spirulina processing. High-temperature drying destroys phycocyanin, proteins, and pigments, reducing market value.

| Drying Method | Nutrient Retention | Commercial Suitability |

| Refractive Window Drying | Excellent | High |

| Vacuum Drying | Very Good | Medium |

| Spray Drying | Low | Bulk only |

| Solar / Sun Drying | Poor | Non-export |

Low-temperature systems preserve quality and enable premium pricing, especially for nutraceutical and export markets. A detailed comparison of methods is discussed in the Greenbubble’s spirulina drying methods comparison guide.

Certification and Market Access

Profit per acre increases significantly when farms are certified and export-ready. Certifications such as USDA Organic, GMP, and HACCP are no longer optional for serious buyers, as explained in detail in why certification is a dealbreaker in spirulina exports.

Certified farms:

- Access higher-paying export markets

- Face fewer price negotiations

- Build long-term buyer trust

- Reduce batch rejection risk

Uncertified farms are typically limited to local bulk buyers at low margins.

Market Strategy: Bulk vs Retail

Profitability also depends on whether spirulina is sold as bulk powder or retail-finished products.

| Model | Annual Profit Potential |

| Bulk B2B | ₹30–45 Lakhs |

| Retail / Branded | ₹45–60 Lakhs |

Retail models require additional compliance, branding, and distribution but significantly improve per-kg realization.

FAQs

Q1. Is spirulina farming profitable on 1 acre?

In most cases, no. A single-acre farm struggles to cover operating costs when realistic expenses and quality requirements are considered.

Q2. What is the minimum land required for profitable spirulina farming?

Commercial profitability typically starts at 2–3 acres, where economies of scale significantly improve margins.

Q3. Does automation really impact profit?

Yes. Automation reduces labor costs, prevents contamination, stabilizes yields, and enables certification-all of which directly improve profitability.

Q4. Can manual spirulina farms achieve organic certification?

Manual farms find it extremely difficult to meet organic, GMP, and HACCP standards due to contamination risks and lack of process control.

Q5. Which drying method gives the highest returns?

Refractive Window Drying provides the best balance of nutrient retention, throughput, and commercial scalability.

Conclusion

Spirulina farming profit per acre is often misunderstood. Small, manual farms rarely generate sustainable returns due to high operating costs, quality risks, and lack of certification readiness. Real profitability comes from scale, automation, low-temperature processing, and strict quality control.

For investors and producers serious about long-term success, the focus should shift from profit per acre to profit per system-where infrastructure, compliance, and market access work together to create a stable, scalable spirulina business. This is the philosophy followed by commercial spirulina operations built with a long-term vision, including projects conceptualized and executed by Greenbubble, where profitability is engineered through process discipline rather than assumptions.