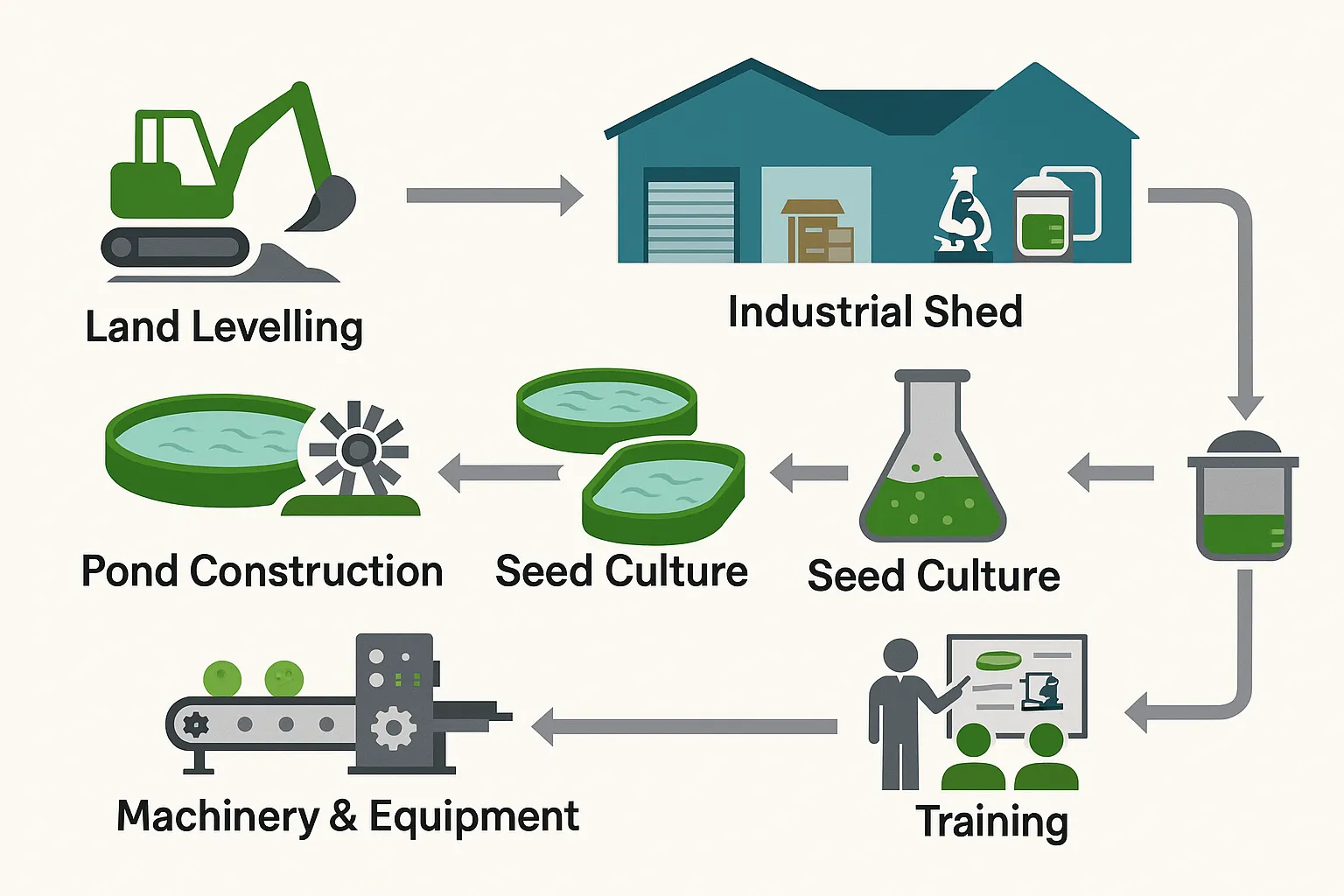

Setting up a spirulina farm from scratch can be overwhelming—but with a turnkey solution, everything from design to documentation is streamlined. A spirulina turnkey project provides a ready-to-run commercial farm setup with integrated machinery, automation, traceability, and compliance systems.

Whether you’re a first-time investor or scaling to meet export demand, understanding each piece of the turnkey puzzle is essential. In this comprehensive guide, we break down every component that contributes to a high-performance, organic-compliant, and market-ready spirulina production facility.

1. Site Selection & Layout Planning

Success begins with a location that supports year-round spirulina growth.

- Climatic suitability: Temperatures of 30–40°C with stable humidity levels are ideal. The site must receive 8–10 hours of sunlight daily.

- Water source compatibility: Availability of borewell or surface water that can be purified through RO or sand filtration. Testing for heavy metals and TDS is essential.

- Soil and land analysis: Determines feasibility for construction, slope grading for drainage, and layout flow.

- Logistics: Access to power lines, transportation, and raw materials.

Layout planning includes:

- Aligned raceways for maximum sunlight

- Segregated zones for drying, cleanroom packaging, and labs

- Flow-optimized paths from pond to pack

- Sanitation pathways and emergency exits

2. Civil Infrastructure

Your spirulina farm must be built for durability, hygiene, and compliance.

- Raceway ponds: RCC or HDPE-lined with graded slopes and drain valves.

- Drainage system: Proper flow management to avoid stagnation or overflow contamination.

- Protective structures: Shade netting, mesh enclosures, or greenhouse roofs to prevent insect entry and regulate microclimate.

- Packaging/drying block: Includes concrete flooring with slope, SS drain channels, anti-slip finish, and UV-protected roofing.

- Power backup: Integration of solar PV panels, inverters, and diesel generators.

See raceway pond construction options

3. Machinery & Equipment Installation

A spirulina turnkey project provides precision-machined, food-grade equipment fully installed and tested.

Core systems include:

- Paddle wheel agitators: Driven by IP-rated motors and SS shafts

- Filtration systems: Modular filtration units with 80–120 mesh screens for removing dirt or debris.

- Harvesting system: CIP enables machines with 500 mesh drums to separate the spirulina from water.

- Dewatering setup: Vacuum filtration or belt press with minimal shear stress

- Dryers: RWD or vacuum dryers that preserve nutrient integrity and comply with organic guidelines

- Grinders & sieves: SS 316 ball mills or ACM with mesh options for uniformity

- Packaging equipment: Nitrogen flushing, heat sealing, and QR-label integration for traceability

Optional equipment:

- Capsule making machines

- Metal detectors and vibro sieves

- Blenders

- Cleaning-in-place (CIP) systems for sanitation

Learn about automated harvesting equipment

4. Automation & Monitoring

Modern spirulina farms rely on real-time data to ensure efficiency and quality.

- IoT Sensors: pH, temperature, light intensity, and turbidity tracking

- Automated dosing: Scheduled nutrient input and paddle wheel control

- SCADA integration: For centralized monitoring and reporting

- Cloud storage: Historical data archives used for audit trails and batch review

Benefits:

- Real-time alerts for deviations

- Optimization of culture cycles

- Prevention of over/underfeeding

5. Quality Control Systems

Turnkey farms include labs and SOPs to ensure you pass organic audits and COA standards.

- On-site lab setup: For live culture microscopy, microbial assessment, and pigment evaluation

- Sampling tools: Sterile pipettes, testing vials, logbooks

- Daily culture logs: Monitoring growth, density, and biomass performance

- Periodic testing: Heavy metals, E. coli, mold, yeast through partnered NABL labs

Lab results also assist in maintaining consistent protein and phycocyanin levels.

Review spirulina quality control guidelines

6. Certifications & Documentation Support

Turnkey projects include full guidance and support on:

Organic Certifications:

- Preparation of organic system plan (OSP)

- Inspection prep for USDA, EU, or India Organic

- Input approval sheets and feed documentation

Food & Facility Compliance:

- GMP layout design and SOPs

- HACCP plan (critical control points during harvesting and drying)

- Pest control protocols and sanitation checklists

- Training logs for staff

Documents provided:

- SOPs for each station

- Traceability forms

- Cleaning schedules

- Raw material intake and rejection logs

7. Packaging, Branding & Market Access

A product’s shelf appeal and compliance depend on how well it’s packaged.

Turnkey services may include:

- Packaging design consultation: Based on target markets (retail/export)

- Material selection: PET jars, foil pouches, glass bottles

- Printing integration: Labels with QR-code traceability and COA links

- Branding services: Logo design, product messaging, compliance marking

Some turnkey firms also offer:

- B2B buyer introductions

- White-label product placement

- E-commerce setup guidance

8. Staff Training & Handover

A world-class system fails without trained personnel. That’s why turnkey projects include:

- On-ground training for operators, lab staff, and QC team

- Training modules: SOP execution, audit response, hygiene practices

- Evaluation system and refresher training kits

- Troubleshooting guides and escalation charts

Most turnkey providers offer 30–90 days of post-installation support to stabilize your operations.

9. Traceability & SCADA Integration

An export-grade spirulina farm requires digital traceability.

- Track input dates, batch IDs, harvest times, operator credentials

- Record equipment run cycles, dryer logs, packaging line history

- Generate PDF audit reports for USDA or buyer review

- Integrate data with ERP or export documentation systems

QR-code enabled labeling linked to traceability boosts transparency and brand value.

10. Post-Handover Support & Expansion Planning

Once operations begin, turnkey vendors provide:

- Remote diagnostics for sensor faults or process errors

- Annual Maintenance Contracts (AMCs) for equipment

- Expansion modules to scale from 1 to 5 acres

- Audit mock sessions to prepare for renewal inspections

- Regulatory updates to keep SOPs current

Estimated Investment for a 1-Acre Turnkey Spirulina Farm

| Component | Estimated Cost (INR) |

| Civil construction | ₹15–18 Lakhs |

| Harvesting equipment | ₹10–12 Lakhs |

| Drying system (RWD/Vacuum) | ₹10–18 Lakhs |

| Packaging + cleanroom | ₹6–8 Lakhs |

| Automation (IoT/SCADA) | ₹3–5 Lakhs |

| Lab + QC setup | ₹5–6 Lakhs |

| Certification & documentation | ₹4–6 Lakhs |

| Total Investment | ₹55–70 Lakhs |

Expansion to 2–3 acres with integrated RWD drying, advanced analytics, and ERP systems may push investment to ₹1.5–2 crore.

Conclusion: Build Smarter with a Turnkey Spirulina Project

Spirulina turnkey projects are not just a shortcut—they are a launchpad for sustainable, compliant, and profitable farming. They consolidate best practices in construction, automation, quality control, and compliance into one seamless deployment.

If you’re looking to set up an export-grade farm or scale an existing pilot, choosing the right turnkey provider can cut down years of R&D and ensure your spirulina business is audit-ready from day one.

Explore our spirulina turnkey project solutions to start your certified spirulina journey with systems built for growth, trust, and long-term ROI.