Many newcomers to algae farming often assume spirulina is a type of seaweed because both thrive in water and share visual similarities. But beyond appearance, spirulina and seaweed have almost nothing in common biologically, structurally, or operationally. Spirulina is a microalgae (cyanobacteria) that thrives in high‑ alkaline freshwater under controlled, lab‑verified conditions. Seaweed, by contrast, is a macroalgae that grows naturally in oceans, coastal belts, and marine farms.

These differences shape every part of their farming processes-from the type of water used to the nutrient inputs, the contamination risks, the harvesting cycle, the processing workflow, COA requirements, labor demands, capital investment, and commercial value. Spirulina is a precision‑managed bioculture requiring daily SOPs, while seaweed is closer to traditional aquaculture with lower operational intervention.

Understanding these distinctions is essential for farmers, entrepreneurs, and investors deciding whether to enter spirulina farming, seaweed farming, or both.

In practice, this distinction becomes very clear when observing commercial spirulina projects built on controlled systems such as those implemented across multiple Greenbubble-designed farms, where spirulina is treated as a regulated food bioculture rather than an aquatic crop. This level of control is fundamentally different from how seaweed is cultivated in open marine environments.

Core Biological Differences

Spirulina and seaweed differ at the most fundamental biological level.

Spirulina (Cyanobacteria / Microalgae)

- Single‑celled, microscopic organism

- Lives in alkaline freshwater (pH 9–11), hostile to contaminants

- Requires controlled light, temperature, pH, and nutrient balance

- Reproduces rapidly-doubling time can be as short as 24 hours

- Can be harvested daily because of fast growth

- Sensitive to ammonia, protozoa, heavy metals, and pH fluctuations

Seaweed (Macroalgae)

- Large, multicellular organism visible to the naked eye

- Grows in oceans, coastal belts, estuaries, and marine farms

- Dependent on tides, currents, salinity, and marine ecology

- Slow growth cycle-may take 1–3 months for a harvestable batch

- Harvested in bulk rather than daily

- Tolerant to wider environmental variations but exposed to ocean pollution

Seaweed behaves like a marine plant; spirulina behaves like a controlled biochemical culture.

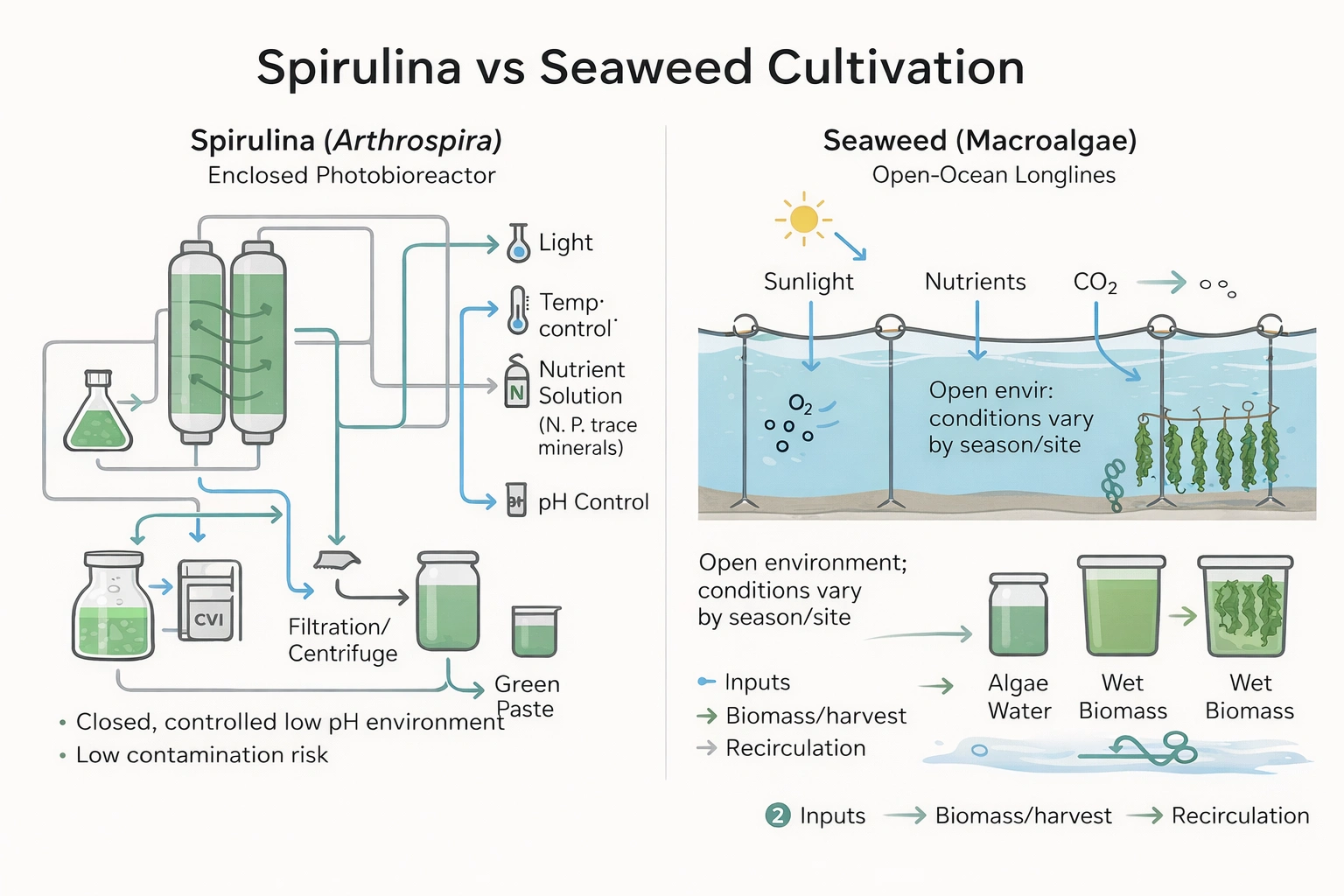

Cultivation System Comparison

| Parameter | Spirulina Farming | Seaweed Farming |

| Organism Type | Microalgae (cyanobacteria) | Macroalgae (marine plants) |

| Water Type | Alkaline freshwater, man‑made ponds | Natural saltwater or brackish water |

| Farming System | Controlled raceway ponds with agitation | Ocean lines, rafts, nets, longlines |

| pH Range | 9–11 (very alkaline) | 7.5–8.5 (neutral/slightly alkaline) |

| Growth Speed | Extremely fast; harvest daily | Slow; harvest after weeks or months |

| Contamination Risk | High; requires strict SOPs, lab tests | Medium; ocean dilution reduces some risks |

| Nutrient Inputs | Precisely dosed nutrients required | Mostly ocean‑supplied nutrients |

| Harvest Frequency | Daily or every alternate day | Seasonal or monthly |

| Processing Needs | Dryers, cleanrooms, lab testing | Mostly washing and sun‑drying |

| COA Requirements | Very strict for food/nutraceutical use | Moderate; varies by industry |

Explore spirulina pond systems:

Raceway Ponds

This is why commercial spirulina farms following Greenbubble-style system architecture rely on engineered raceway ponds, continuous agitation, and SOP-driven monitoring, whereas seaweed farming remains dependent on natural marine cycles that cannot be tightly controlled.

Nutrient Input Differences

Spirulina Nutrient Requirements

Spirulina cannot survive on plain water; it needs a carefully formulated culture medium.

- Sodium bicarbonate (alkalinity stabilizer)

- Potassium nitrate (primary nitrogen source)

- Magnesium sulfate (enzyme function)

- Iron sulfate (pigment formation)

- Calcium chloride and trace minerals

- Pure freshwater free from heavy metals

Daily dosing, pH checks, and nutrient balancing are essential. Poor nutrient management leads to:

- Reduced density

- Pale or yellow spirals

- Low protein and phycocyanin levels

- COA failure

In Greenbubble-backed spirulina farms, nutrient formulation and dosing are treated as a quality-control function rather than a farming task. This ensures that protein levels, phycocyanin content, and COA parameters remain consistent across batches—something that is not possible in ocean-fed seaweed systems.

Seaweed Nutrient Requirements

Seaweed absorbs nutrients passively from the ocean:

- Nitrogen

- Minerals

- Trace elements

- Natural organic matter

Artificial nutrients are rarely needed, making seaweed farming cheaper-but also harder to control.

Learn more about spirulina nutrient systems:

Spirulina Farming Consultancy

Water System Differences

Spirulina

- Grown in engineered ponds, free from soil or marine contaminants

- Requires stable temperature (28–38°C)

- Needs consistent alkalinity for spirulina to dominate over contaminants

- Must be protected from rainfall dilution

- Water cannot contain urea, ammonia, pesticides, or heavy metals

- Water is recycled and maintained through SOPs

Seaweed

- Grown entirely in open‑water environments

- Dependent on natural tides, salinity, and temperature fluctuations

- Exposed to microplastics, oil spills, marine waste, and industrial runoff

- Prone to damage during storms and monsoons

- Requires permits for coastal farming zones

Processing Workflow Differences (Greatly Expanded)

Spirulina Processing Steps

- Daily harvesting using 30–60 micron mesh filters

- Dewatering using assisted or automated systems to reduce moisture

- Drying using RWD dryers, vacuum dryers, or spray dryers

- Milling into fine powder under hygienic conditions

- Packing inside a GMP‑style cleanroom

- COA testing for each batch before selling

Spirulina requires food‑grade equipment, stainless steel contact surfaces, and complete contamination control.

Commercial spirulina units designed using Greenbubble processing workflows integrate dewatering, RWD drying, and cleanroom packing into a single controlled chain. This minimizes manual handling, reduces contamination risk, and ensures that each batch meets export-grade COA requirements—standards that are structurally incompatible with seaweed’s open-air processing model.

Explore processing systems:

Assisted Dewatering Systems

RWD Drying Systems

Packing Systems

Seaweed Processing Steps

- Harvest using boats or coastal workers

- Rinse to remove sand, salt, shells, and marine organisms

- Sun‑dry on mats or racks (low‑cost method)

- Mechanically dry for higher‑value applications

- Cut or shred based on final use

- Package for fertilizer, food, or industrial products

Seaweed processing is largely manual and inexpensive but yields lower‑value final products.

Profitability Comparison

Spirulina Farming Profitability

- High‑value product used by nutraceutical brands

- Selling price ranges from ₹800 to ₹2,800 per kg depending on drying method

- Daily harvesting enables consistent monthly revenue

- Requires skilled operators, strict SOPs, and lab support

- Premium spirulina enables private‑label and export contracts

This pricing stability is consistently observed in export-oriented spirulina farms operating on Greenbubble-standard SOPs, where quality consistency enables long-term nutraceutical and private-label contracts.

Seaweed Farming Profitability

- Typically sold at ₹20 to ₹120 per kg depending on species

- Often used for fertilizers, thickeners, and animal feed

- Revenue depends heavily on coastal permissions and weather

- Lower operational cost but limited margins

- High‑value seaweed (like nori) requires specialized conditions

Profitability Winner: Spirulina, due to better price, premium markets, and export demand.

Market Differences

Spirulina Markets

- Nutraceuticals & supplements

- Sports nutrition

- Functional foods (smoothies, beverages, gummies)

- Cosmetics & skincare

- Pharmaceuticals

- Export markets (US, EU, Japan)

Seaweed Markets

- Biofertilizers

- Animal feed

- Hydrocolloids (agar, alginate, carrageenan)

- Edible seaweed (nori, kelp)

- Bioplastics and industrial gum

Seaweed has a wide market but far lower value per kg compared to spirulina.

COA (Certificate of Analysis) Requirements

Spirulina COA

- Protein percentage (must be high)

- Phycocyanin content

- Moisture levels

- Microbial load (TPC, yeast, mold, coliform)

- Heavy metals (Pb, As, Cd, Hg)

- Pesticides (should be zero)

- Mycotoxins

Seaweed COA

- Moisture

- Heavy metals

- Basic nutrient profile

- Microbial safety (less strict)

Spirulina requires deeper chemical and microbial testing because it is consumed as a concentrated supplement.

Which Is More Complex to Grow?

Spirulina

- Requires daily monitoring of pH, nutrients, temperature, density

- SOPs must be followed precisely

- Sensitive to contamination from protozoa, mold, ammonia, or urea

- Requires training, lab testing, and controlled infrastructure

Seaweed

- Naturally grows with minimal intervention

- Fewer SOPs needed

- Vulnerable to weather, storms, and ocean pollution

- Lower‑maintenance but lower‑profit model

FAQs

Q1: Is spirulina a type of seaweed?

No. Spirulina is a microalgae (cyanobacteria), while seaweed is macroalgae.

Q2: Which is more profitable: spirulina or seaweed?

Spirulina generates higher profit per acre due to premium pricing and global demand.

Q3: Does spirulina grow in the ocean?

No. Spirulina requires highly alkaline freshwater environments.

Q4: Can a seaweed farmer switch to spirulina?

Yes, but spirulina requires controlled systems, lab support, and specialized SOPs.

Q5: Which is easier to grow?

Seaweed is easier, but spirulina is more profitable.

Conclusion

Although spirulina and seaweed are both aquatic, photosynthetic organisms, they differ completely in biology, farming techniques, nutrient needs, processing, and commercial value. Spirulina’s controlled, technology-driven cultivation system allows it to achieve higher purity, richer nutrient content, and superior profitability. Seaweed remains valuable in bulk industries, but spirulina dominates high-value nutraceutical and export markets.

Understanding these differences helps farmers, investors, and agri-startups make informed decisions about which algae sector best aligns with their goals.