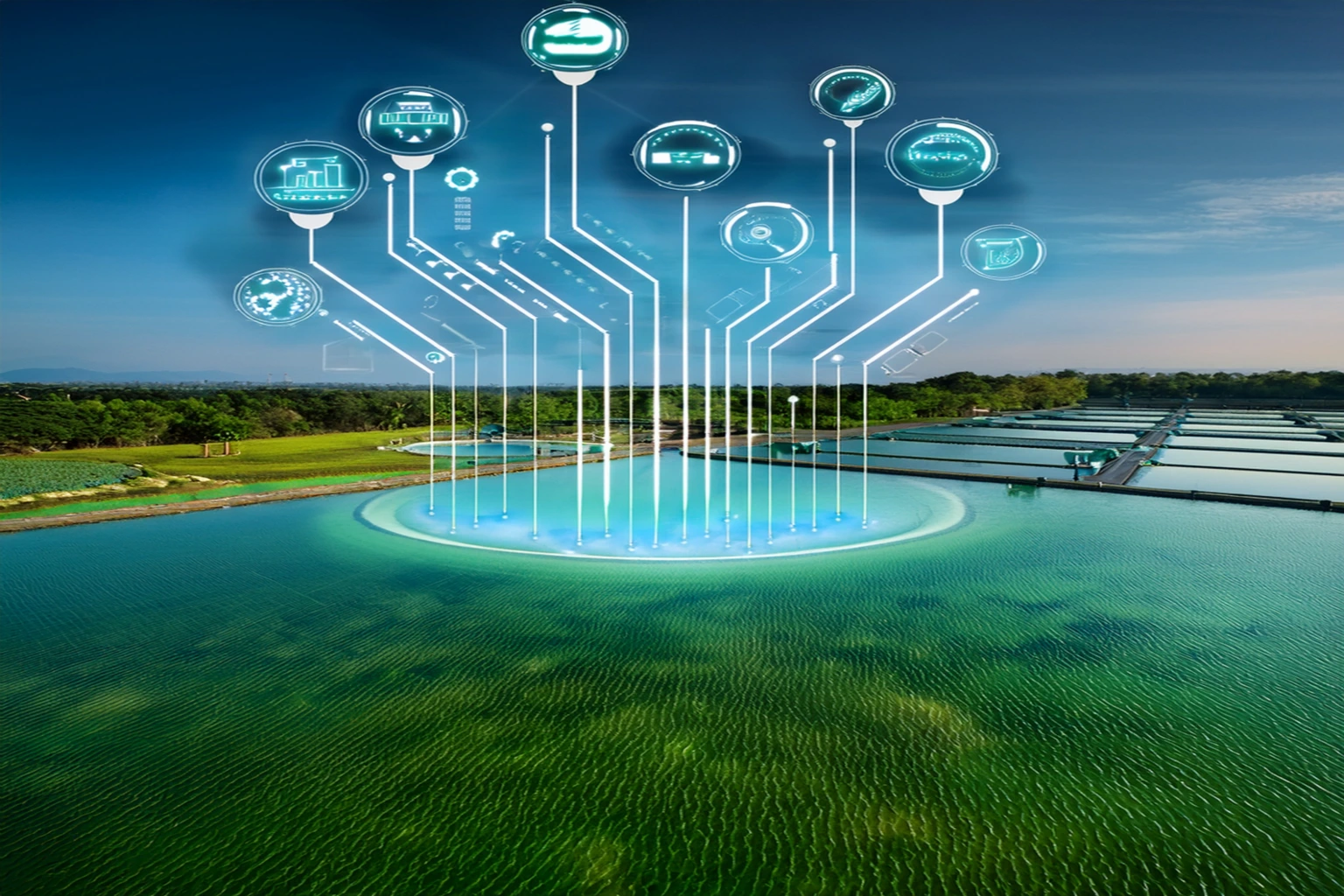

In today’s age of smart agriculture, the integration of IoT (Internet of Things), automation, and SCADA (Supervisory Control and Data Acquisition) systems has transformed traditional farming models. One of the most promising beneficiaries of this transformation is spirulina farming—a high-value, nutrient-rich aquaculture sector.

As spirulina gains popularity for its health benefits and commercial potential, implementing smart controls in its production process has become essential for maintaining quality, maximizing yield, and staying compliant with export standards.

Why IoT Matters in Spirulina Cultivation?

Spirulina cultivation requires a controlled aquatic environment with precise regulation of pH, temperature, light, and nutrient concentration. Traditional manual methods fall short in consistently maintaining these conditions—leading to inconsistent quality, contamination risks, and higher labor costs.

IoT-based farm automation systems solve this by providing:

- Real-time monitoring

- Automated adjustments

- Remote data access

- Predictive alerts for anomalies

These smart features allow spirulina farmers to reduce operational errors and increase yield quality.

→ For a foundational look into the value of tech-driven cultivation, explore our post on Automation in Spirulina Farming

Key Parameters Monitored in Spirulina Algae Farming

The production of spirulina is sensitive to a narrow range of environmental conditions. Even slight deviations can reduce protein content or cause contamination.

IoT sensors help monitor and control:

| Parameter | Ideal Range | Sensor Type |

| pH Level | 9–11 | pH Sensor |

| Temperature | 30–35°C | Temperature Probe |

| Light Intensity | Moderate, diffused sunlight | Lux/Photodiode Sensors |

| Water Level | Stable with evaporation loss tracking | Ultrasonic Sensor |

| Nutrient Concentration | Based on C:N:P ratio | Nitrogen and Dissolved Oxygen Sensors |

With these sensors integrated into a central SCADA dashboard, farm managers can access real-time alerts and historical trends.

What Is SCADA & How It Supports Spirulina Farming?

SCADA systems are the brains behind smart spirulina farms. They collect sensor data, visualize it through dashboards, and allow operators to make remote adjustments. SCADA systems also provide:

- Alarm notifications for deviation from optimal ranges

- Trend analysis for predictive maintenance

- Batch traceability and audit logs required for organic certifications

In a commercial spirulina setup, SCADA integration ensures data-backed decision-making and operational transparency.

→ See a real-world application in our success story with Parry Nutraceuticals’ 100-acre automated spirulina facility

Benefits of IoT & Smart Controls in Spirulina Agriculture

1. Improved Quality Consistency

Automation minimizes human error in maintaining pH and temperature, ensuring uniform spirulina protein content across batches.

2. Faster Detection of Contamination Risks

Real-time data helps detect microbial growth conditions early, reducing the danger of spirulina contamination.

3. Reduced Operational Costs

While initial setup is capital-intensive, long-term savings come from reduced labor dependency and energy-efficient processes.

4. Data-Driven Certification Readiness

IoT data supports batch-wise compliance for USDA Organic, GMP, and EU Organic audits.

→ Learn how proper environmental control is critical for Spirulina Quality Control in Mass Production

IoT Infrastructure in a Spirulina Farm: What You Need

Hardware Components:

- Waterproof industrial-grade sensors (pH, Temp, EC)

- GSM or Wi-Fi-based IoT nodes

- Smart actuators for nutrient dosing

- Solar-powered backup modules (for off-grid setups)

Software/SCADA Layer:

- Web-based dashboard

- Cloud storage for data logging

- Alert-based mobile notifications

- API access for advanced farm management software

When layered correctly, these systems allow full visibility over your spirulina cultivation in India or any other geography.

Use Case: IoT in Large-Scale Spirulina Cultivation

Let’s consider a commercial spirulina algae farm producing 2000kg/month. Manual monitoring would require 3–4 full-time employees. With IoT automation, the same farm can be managed by 1 trained operator, using smartphone-based dashboards to manage multiple ponds.

Key Results:

- 30% increase in yield consistency

- 40% reduction in energy and water usage

- 50% faster issue detection and resolution

- Qualifies for higher price of spirulina in premium markets

Cost Consideration & Government Support

Setting up an IoT-enabled spirulina facility involves upfront investment in sensors, controllers, and SCADA integration. Typical costs for a 1-acre IoT-enabled spirulina farm can range from ₹75 to 95 lakhs, depending on automation depth.

While not all components are covered, some agricultural schemes in India (especially under Digital Agriculture Missions and aquaculture subsidies) offer partial funding.

→ Discover additional support in our guide to Government Grants and Subsidies for Spirulina Mass Production

IoT, Automation & the Future of Spirulina Farming in India

India has emerged as a leader in spirulina cultivation, thanks to favorable climatic conditions and a growing focus on organic, plant-based nutrition. As the market matures, IoT in agriculture will become a differentiator—especially for export-ready and GMP-certified facilities.

With sensors becoming more affordable and cloud platforms more accessible, spirulina farmers who adopt smart agriculture systems today will be tomorrow’s market leaders.

→ For market dynamics and pricing trends, see Market Trends & Opportunities in Spirulina Farming

Conclusion: Digitize to Optimize

Integrating IoT and SCADA in spirulina farming is no longer a luxury—it’s a competitive necessity. Whether you’re a small-scale grower or managing an industrial facility, smart automation helps you:

✅ Maintain consistent product quality

✅ Reduce operational and labor costs

✅ Meet global certification and compliance standards

✅ Improve traceability and market access

👉 Want to upgrade your spirulina farm with smart automation?

Explore our Turnkey Spirulina Farming Solutions or contact us to build your own IoT-enabled spirulina facility.