With rising global demand for nutrient-rich spirulina powder and supplements, building a HACCP-compliant spirulina facility is now critical for any serious producer. Compliance with food safety standards like HACCP (Hazard Analysis and Critical Control Points) not only ensures product safety but also opens doors to premium markets and exports.

This guide walks you through the key components of building and managing a HACCP-compliant facility for spirulina algae farming—from site layout and equipment to documentation and certification.

Why HACCP Compliance Matters in Spirulina Farming

Spirulina is consumed as a functional food or supplement—often in capsule, tablet, or spirulina mix form. But as a sensitive algal biomass, it is also vulnerable to contamination if not handled correctly.

HACCP ensures:

- Identification and control of potential biological, chemical, and physical hazards

- Cleaner processing environment

- Better spirulina benefits and side effects transparency

- Greater trust among B2B buyers and D2C customers

- Eligibility for export and organic certification

→ Learn more about the importance of consistent testing and hygiene in our quality control guide for spirulina production.

Step 1: Choose the Right Site and Layout

A HACCP-compliant spirulina facility starts with site selection and zoning:

Key Requirements:

- Should be located away from chemical-intensive agricultural zones or heavy industry

- Access to clean water sources, free of heavy metals or synthetic dyes

- Segregated layout to separate algae culture zones, dewatering, drying, packaging, and storage areas

→ See how facility hygiene contributes to compliance in automation in spirulina processing.

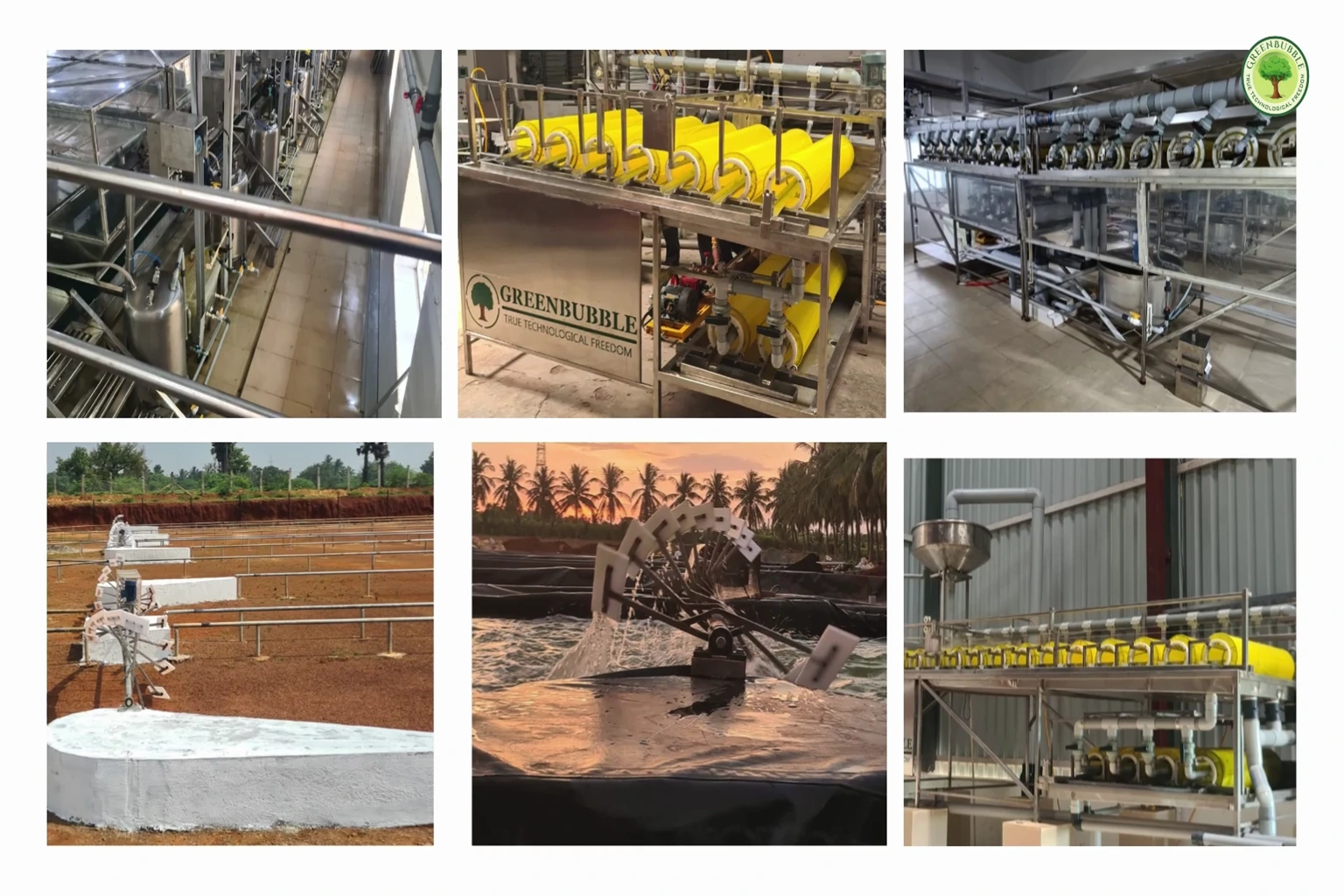

Step 2: Use Food-Grade, Certified Equipment

All equipment that comes in contact with spirulina must be non-reactive, easy to sanitize, and compliant with food safety norms.

Equipment Recommendations:

- SS 316-grade steel tanks and harvesters

- Low-heat drying systems (vacuum or refractive window preferred)

- Automated harvesting and dewatering systems to minimize human contact

- Clean-in-place (CIP) systems for internal equipment cleaning

→ Check out our auto discharge dewatering system designed for organic and HACCP compliance.

Step 3: Build a Traceable Quality Control System

Spirulina’s safety depends not just on farming practices, but also on documentation and traceability.

Documentation Must Cover:

- Batch-wise COAs (Certificate of Analysis)

- Daily logs of pH, temperature, contamination risks

- Cleaning and sanitation logs

- Supplier certifications for inputs (e.g., OMRI-listed nutrients – if organically producing only)

This not only supports HACCP audits but also provides assurance to end-consumers who are increasingly curious about spirulina nutrition facts and sourcing.

Step 4: Hazard Analysis and Critical Control Points

This is the core of HACCP. You’ll need to identify and control every possible risk point.

Examples of Common Hazards in Spirulina Processing:

| Process Stage | Potential Hazard | Control Measure |

| Cultivation | Water contamination (metals/microbes) | Weekly lab testing |

| Harvesting | Cross-contamination | SS equipment & gloves |

| Drying | Nutrient degradation or microbial growth | Temperature monitoring |

| Packaging | Air/moisture exposure | Vacuum-sealed packaging |

Step 5: Staff Training & Hygiene Protocols

Even the most advanced equipment won’t ensure safety without trained staff. Hygiene is essential, especially during spirulina powder handling and packaging.

Training Areas:

- Proper glove, mask, and lab coat usage

- Avoiding direct contact with algae

- Cleaning and disinfection protocols

- Understanding HACCP points and documentation responsibilities

Step 6: HACCP Documentation & Certification

Once your processes are defined, hazard points controlled, and records in place, it’s time to seek HACCP certification.

You’ll Need:

- HACCP Plan tailored to spirulina production

- Master documents: SOPs, sanitation plans, risk analysis

- Verification reports and corrective action logs

- Internal audits every 6 months

You can get certified through accredited bodies such as SGS, Bureau Veritas, or HACCP-empaneled auditors in India.

Step 7: Stay Aligned With Other Certifications

If you’re aiming to sell to health-conscious consumers, certifications are your ticket to premium pricing. HACCP is often the baseline for:

- USDA Organic or EU Organic certification

- GMP (Good Manufacturing Practices)

- ISO 22000

- Export approvals in U.S., EU, and Asia-Pacific markets

→ Learn how certifications impact the price of spirulina and profitability in global markets.

Safety Considerations: Spirulina Benefits vs. Risks

HACCP doesn’t just help with compliance—it ensures your end product actually delivers the spirulina benefits consumers expect, while minimizing health risks.

Key Consumer Benefits of Spirulina:

- High spirulina protein content for vegetarians and vegans

- Iron-rich profile, especially spirulina benefits for women

- Detoxification and immune support

- Benefits of spirulina for skin and energy levels

Risks to Avoid (If Not Compliant):

- Danger of spirulina contamination (heavy metals, bacteria)

- Side effects like nausea, headaches, or allergic reactions

- Poor batch traceability leading to legal or recall issues

→ Explore our blogs to understand more details in how safe is spirulina for consumption

Conclusion: Invest in Safety, Earn Consumer Trust

A HACCP-compliant spirulina facility isn’t just a regulatory checkbox—it’s a business enabler. From securing bulk buyers and D2C trust to tapping into export markets, food safety and process traceability are now non-negotiable.

By implementing structured layouts, food-grade equipment, risk assessment, and continuous documentation, you build more than just a facility—you build a brand that stands for quality, safety, and true spirulina benefits.

👉 Need help setting up your HACCP-ready spirulina operation?

Explore our turnkey spirulina farming solutions or contact us directly for a custom consultation.