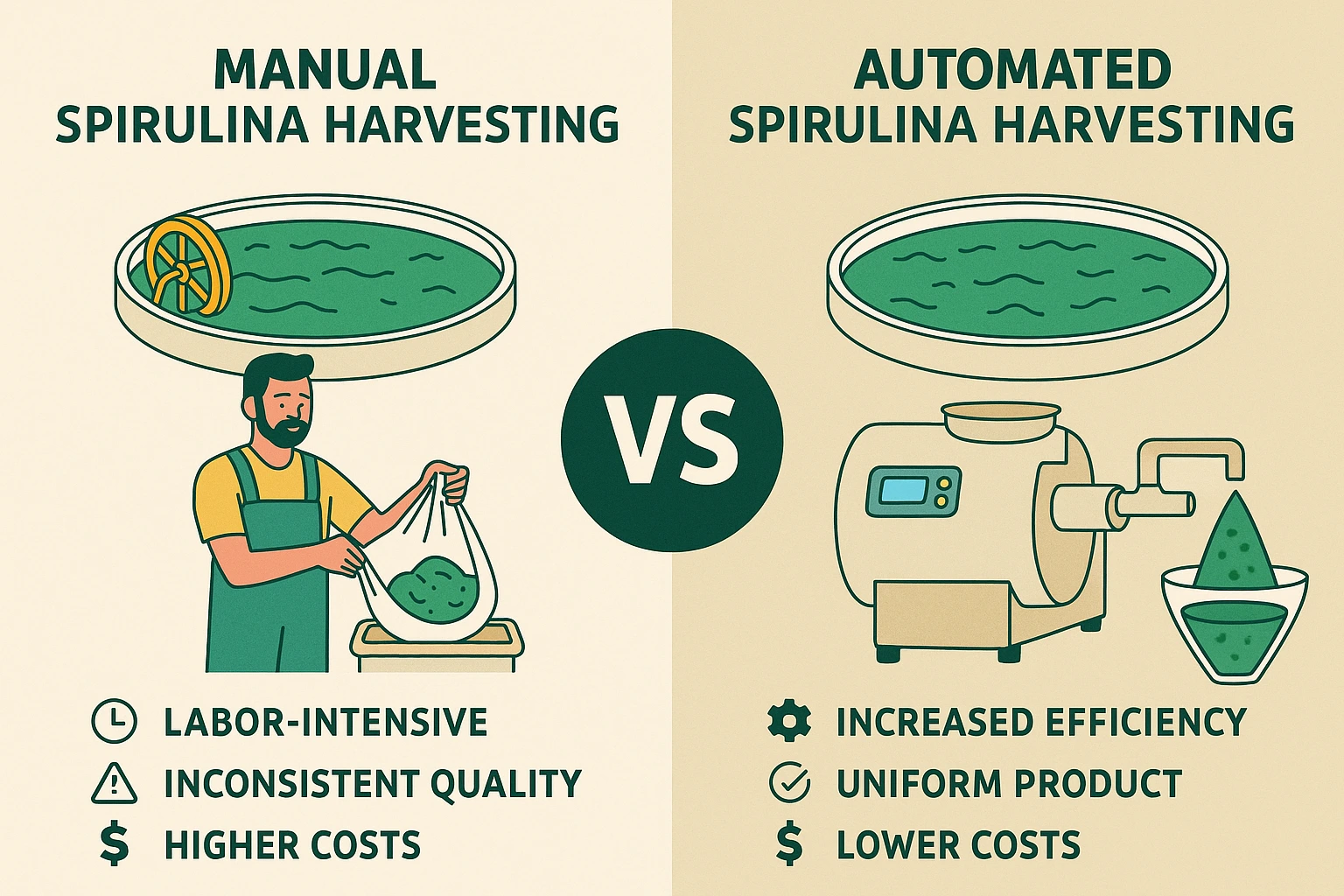

As spirulina farming scales from small pilot units to commercial-grade production across 1-acre and 5-acre setups, harvesting becomes a make-or-break stage. This is the point where spirulina biomass transitions from live culture to a saleable, certifiable, and premium-grade product. However, spirulina is fragile, sensitive to oxidation, and degrades quickly if not processed efficiently. Manual harvesting introduces delays, inconsistency, and contamination risks—all of which can compromise organic certifications and market value.

Automation in spirulina harvesting is not a futuristic add-on. It is central to maintaining biomass quality, supporting regulatory compliance (USDA Organic, EU Organic, GMP, HACCP), and reducing operating costs in a scalable and traceable way. In this blog, we explain why automated harvesting is essential, what systems to use, and how to implement them profitably.

Why Harvesting Automation Matters

1. Quality Preservation

Spirulina begins to degrade within 10 to 20 minutes of exposure to air and light once separated from its culture medium. Essential compounds such as:

- Phycocyanin (blue pigment, antioxidant)

- Beta-carotene (pre-vitamin A)

- Vitamin B12 and amino acids

…are heat-sensitive and oxidize quickly. Delays in harvesting and then drying due to manual bottlenecks often lead to:

- Poor taste and smell

- Loss of pigment

- Lower protein values

Automated filtration and dewatering systems reduce time-to-process, help maintain low temperatures, and ensure sealed transfer between stages—protecting the bioactivity of your final product.

2. Organic Certification Compliance

Organic certification for spirulina (USDA, EU, India Organic) requires documentation, traceability, and reduced human intervention in critical production steps. Harvesting is one of the highest-risk phases for cross-contamination.

Manual processes using mesh cloths, plastic basins, and open transfers increase:

- Microbial exposure

- Material leaching from non-food-grade containers

- Inconsistent moisture retention

Automation provides:

- Enclosed systems using SS 316-grade or food-grade polymer components

- Batch-based logging integrated with SCADA

- Automatic cleaning cycles

Learn how automation improves traceability

3. Labor Reduction & Scalability

One of the biggest barriers to scaling spirulina farms beyond 1 acre is labor cost and coordination. Manual harvesting requires 3–5 staff per batch and can only process 1–2 raceways per shift.

Automated systems reduce human labor by 80–90%, allowing farms to:

- Process 4–6 raceways simultaneously

- Reduce error margins

- Standardize SOPs across shifts

The result is better utilization of labor and infrastructure, making operations leaner and more profitable.

Key Components of an Automated Harvesting System

A robust automation setup covers every step of the harvesting pipeline—from filtration to moisture control and logging.

1. 80-Mesh Pre-Filters

Placed at outlet valves, these remove any dirt and debris from the incoming culture.

- Use high-tensile nylon or stainless steel

- Enable reuse, easy cleaning, and certification compliance

2. Harvesting machine

Use rotary drum based filters with fine 500 mesh filters to gently separate spirulina from the culture.

- Use 316 SS for the body

- Retain biomass while allowing culture to return to raceways

- Easily washable with Clean in place systems

2. Auto-Dewatering Units

This is where harvested biomass is concentrated to a paste. Options include:

- Vacuum-assisted filtration: Gentle, enclosed

- Screw-press dewatering: Energy-efficient, good for scale

Benefits include:

- Reduced drying time

- Improved pigment preservation

- Less risk of microbial contamination

Explore our assisted dewatering systems

3. Automated Valves and Transfer Pumps

These allow you to:

- Transfer culture at scheduled times

- Control flow speed to avoid damage

- Flush and clean the system after each cycle

4. SCADA Integration and Data Logging

Each harvest batch can be tracked through:

- Culture pH, turbidity, temperature

- Start/stop time

- Operator and batch ID

- Output weight

This allows farms to maintain audit logs and meet export compliance.

Browse our harvesting equipment solutions

5. Cleanroom-Ready Transfer Lines

If you’re drying spirulina in a low-heat, enclosed cleanroom facility, use stainless steel or silicone-grade piping to transfer paste from the dewatering station to dryers without exposure to open air.

Benefits of Automated Spirulina Harvesting

Reduced Labor Dependency

- Less dependence on skilled labor

- One operator can manage 4–6 systems

- Lower seasonal staff turnover challenges

Improved Product Quality

- Consistent paste texture for capsule or tablet formulation

- Lower microbial counts = longer shelf life

- Fewer rejected batches

Easier Certification & Export Compliance

- Automated logs support USDA, EU, and FSSAI audits

- Consistency supports organic label claims

Cost Efficiency

- Reduced electricity and water use

- Lower post-processing losses

- Optimized turnaround = faster ROI

Traceability & Reputation

- Track every step with QR-code enabled logs

- Build buyer confidence with clean-label proof

Case Study: Manual vs Automated Harvesting in Tamil Nadu

A farm in Namakkal, Tamil Nadu processed spirulina manually for 2 years. Their main issues included:

- High microbial counts

- 4–6 hour drying and upto 48 hours in seasons

- Labor-intensive filtering

Post-automation (filtration + vacuum dewatering):

- Yield per raceway rose by 18%

- Phycocyanin levels increased by 22%

- Labor dropped from 5 to 1.5 full-time equivalents

- Product shelf life improved by 6 months

- Passed USDA Organic audit in first attempt

Choosing the Right Harvesting Equipment

When investing in harvesting automation, focus on:

Material Standards:

- SS 316 or food-grade plastic

- Non-reactive, corrosion-resistant

Modular Design:

- Easy to expand

- Fits existing raceways, drying systems

Organic Certification Ready:

- OMRI-approved or compliant parts

- Sealed systems for contamination prevention

Power Efficiency:

- Low-voltage pumps and timers

- Backup compatibility with solar

Ease of Cleaning:

- CIP (clean-in-place) setup

- Tool-free disassembly

Implementation Guide for Spirulina Farmers

Phase 1: Assessment

- Map current harvesting pain points

- Calculate harvest volume per day

Phase 2: Pilot

- Install 1–2 automated filtration and dewatering units

- Measure ROI over 2 months

Phase 3: Full Rollout

- Scale across farm

- Link with SCADA and drying control

Phase 4: Staff Training

- SOPs for start-up, shutdown, sanitation

- Troubleshooting charts

Cost Breakdown: Mid-Scale Harvesting Automation

| Equipment Component | Estimated Cost (INR) |

| Pre-Filtration System (80-mesh) | ₹0.5–1 Lakhs |

| Harvesting system | ₹6 – 8 Lakhs |

| Vacuum Dewatering Unit | ₹4– 5 Lakhs |

| Pumps & Automated Valves | ₹1–2 Lakhs |

| SCADA/Cloud Logging Setup | ₹3–5 Lakhs |

| Transfer Pipes & Connectors | ₹0.5–1 Lakhs |

| Total Estimated Setup | ₹15–22 Lakhs |

Note: Prices may vary based on capacity, automation level, and power source.

Conclusion: Automate to Sustain and Scale

Manual spirulina harvesting may work for hobby farms or test plots, but for commercial, organic, or export-focused operations, it falls short. The risks of contamination, inconsistency, and labor overhead are too high.

Automated harvesting preserves the quality of your biomass, ensures consistency, and enables your farm to scale with confidence. It also unlocks the ability to meet USDA Organic, EU Organic, GMP, and HACCP standards.

If your goal is premium product certification, export readiness, or streamlined operations, automation is not optional. It is non-negotiable.

Ready to modernize your harvesting system? Explore our turnkey harvesting solutions to get started today.