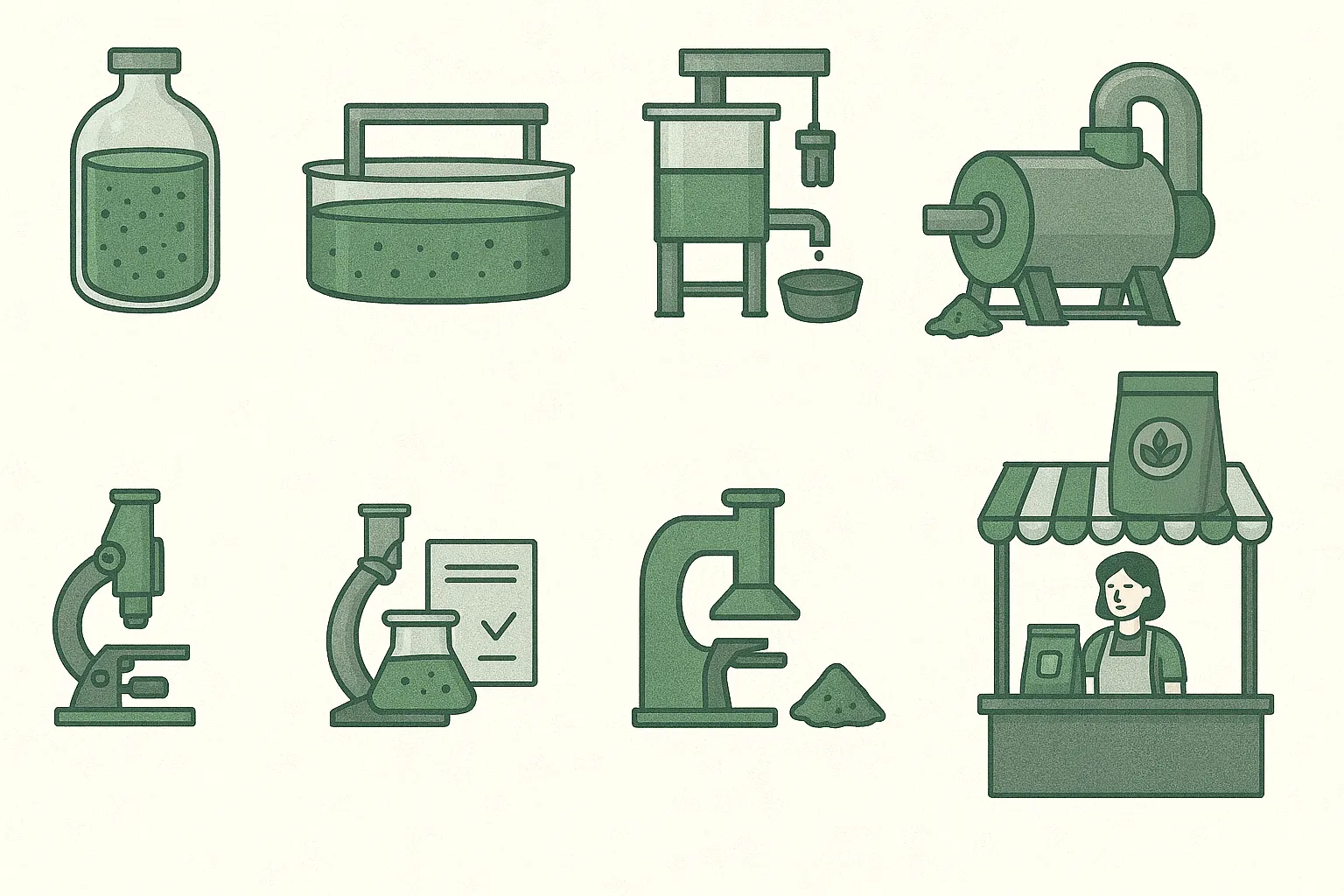

The success of any spirulina farming operation depends on mastering its biological and operational life cycle. Unlike traditional crops, spirulina doesn’t follow seasons—it follows science. From the first drop of starter culture to the final bag of dry powder, every stage in spirulina algae farming requires precision, consistency, and hygiene.

In this blog, we break down the complete life cycle of spirulina cultivation, including internal links to help you go deeper into each phase—from inoculation and culture expansion to harvesting, drying, and packaging.

Inoculation – Seeding the Spirulina Culture

Spirulina farming begins with inoculation, the process of introducing a healthy, lab-grown starter culture into a larger tank or raceway pond. This starter culture is carefully selected based on purity, species (commonly Arthrospira platensis), and activity level.

Before inoculation, the culture medium is prepared using:

- Sodium bicarbonate (carbon source)

- Nitrogen (urea or nitrate)

- Phosphates and trace minerals

The nutrient ratio (C:N:P of approximately 24:0.14:1) is critical for a healthy start.

Environmental conditions must be tightly controlled:

- pH: 9–11

- Temperature: 30–35°C

- Light: Preferably natural and diffused

The inoculated medium is monitored closely for 3–5 days, with agitation to prevent settling and promote gas exchange.

→ Learn how to get your nutrient profile right in Spirulina Cultivation Best Practices and Techniques

Culture Expansion – Scaling the Volume

Once the seed culture stabilizes, it’s gradually transferred to larger tanks—a phase known as culture expansion. This step can take up to two months, depending on the farm’s scale and ambient conditions.

At this point, you begin:

- Scaling from small lab tanks to raceway ponds

- Regular testing of pH, temperature, and color density

- Controlled dosing of nutrients and clean water top-ups

Continuous paddlewheel agitation ensures even nutrient distribution and photosynthesis. Any sudden drop in color intensity or foam formation could indicate contamination or nutrient imbalance.

For new farms, this is where IoT in agriculture becomes valuable. Sensors track key metrics in real-time, allowing for automated alerts and corrective actions.

→ Read more about how smart farming improves efficiency in Automation in Spirulina Farming

Maintenance Phase – Daily Monitoring & Corrections

At full scale, your spirulina culture enters a maintenance cycle, where you aim for steady biomass growth with minimal risk. This phase continues indefinitely with proper harvesting and inoculation planning.

Key actions:

- Monitor pH daily and adjust with soda ash

- Keep temperature within range using shade nets or greenhouse covers

- Clean paddlewheels, mesh, and tank corners to prevent biofilm

- Test weekly for contaminants (bacteria, metal traces)

Culture density is often tracked using Secchi disks or spectrophotometers. Once optimal growth is observed (typically in 5–7 days post-harvest), it’s time to collect the spirulina.

→ Learn more about testing protocols in How to Test Spirulina Quality

Harvesting – Separating Biomass from Water

Harvesting begins when spirulina reaches its peak density and nutritional value. This is done by filtering the culture through fine mesh or using automated dewatering systems.

Steps:

- Stop agitation

- Let solids settle briefly

- Use gravity-fed filters or pumps to collect the spirulina biomass

For larger farms, automated assisted dewatering systems are preferred—they reduce contamination, save labor, and improve hygiene.

→ Explore scalable harvesting tools in Harvesting Equipment Solutions

The filtered biomass now resembles green paste and must be immediately processed to preserve quality.

Dewatering & Drying – Preserving Nutrients

Fresh spirulina contains over 90% water and spoils quickly. Dewatering is the intermediate step before drying, where excess moisture is squeezed out using cloth presses or auto-discharge systems.

Then comes drying—the most sensitive step in the entire life cycle. Low-heat drying systems are ideal, as high temperatures can destroy spirulina’s proteins, enzymes, and pigments.

Preferred methods:

- Vacuum drying (nutrient retention)

- Refractive window drying (solar + low heat hybrid)

- Avoid spray drying for organic farms—it denatures nutrients

The goal is to reduce moisture to <7%, ensuring a shelf-stable, nutrient-rich product.

→ Compare your options in Spirulina Drying Equipment Solutions

Packaging & Storage – Ensuring Shelf Life

Once dried, spirulina must be stored in a moisture-proof, oxygen-barrier packaging. Typical options include:

- HDPE bottles for spirulina capsules

- Food-grade pouches for spirulina powder

- Vacuum-sealed bricks for bulk shipments

Each batch is labeled with:

- Harvest date

- Nutritional specs

- COA reference number

Proper storage in cool, dry spaces prevents spoilage and extends shelf life up to 24 months.

→ Understand packaging standards in Packing Systems for Spirulina

Certification & COA – Verifying Quality

Your spirulina is now ready for market—but before selling, you need a Certificate of Analysis (COA) to prove batch quality.

Key metrics include:

- Protein content

- Iron and carotenoids

- Heavy metals (within limits)

- Microbial safety (no E. coli, Salmonella)

This document helps justify premium pricing and supports organic/GMP certifications.

Economics – How the Life Cycle Impacts Cost

Each stage in the spirulina life cycle contributes to production costs. Delays, contamination, or poor processing can reduce yield or quality—affecting pricing and profitability.

Typical cost per kg:

- Non-organic: ₹600–₹900/kg

- Organic, certified: ₹1200–₹2200/kg

Automation and quality control may increase setup costs but lead to better margins in the long run.

→ Read the full breakdown in Spirulina Farming Costs and Profits

Conclusion: Master the Cycle, Maximize the Return

Understanding and managing each step of the spirulina life cycle is the key to consistent quality, lower operational cost, and better pricing. From seeding and scaling to harvesting and drying, every phase plays a role in your farm’s success.

With the right tools, trained team, and smart layout planning, even a small farm can deliver premium-grade spirulina algae ready for local and global markets.

👉 Need help setting up or optimizing your spirulina lifecycle management?

Contact Greenbubble for turnkey spirulina farm design, automation systems, and certification support.