As spirulina gains recognition as a high-value superfood packed with essential nutrients, more entrepreneurs are eyeing it as a promising and sustainable agribusiness. It is one of the few algae that can be grown commercially under controlled environments, offering long-term profitability if managed correctly. But profitable spirulina algae farming requires more than just enthusiasm—it demands robust infrastructure, IoT-driven automation, expert-led lab support, and uncompromising quality control. In this comprehensive guide, we walk through the full spirulina farming setup, from pond construction to packaging, aligned with both organic and commercial production standards in India and internationally.

Why Spirulina Farming?

Spirulina is a nutrient-dense blue-green algae rich in protein (60%+), iron, carotenoids (including β-carotene), essential fatty acids like GLA, and powerful antioxidants. It’s regarded as a superfood by WHO and NASA. With the increasing market demand for spirulina and its export opportunities, especially in health-conscious and organic markets, spirulina farming in India has emerged as a scalable and high-potential venture.

However, success requires careful planning, environmental control, and continuous monitoring of both the culture and process.

Step 1: Site Selection & Preparation

Choosing the Right Location

- Sunlight Access: Spirulina depends on strong natural sunlight for optimal photosynthesis. Select locations with 8–10 hours of uninterrupted sun exposure.

- Water Source: A clean and consistent water supply is essential. Borewell water filtered through filtration such as sand and UV is recommended. Water must be tested periodically for heavy metals, salinity, and microbial load.

- Temperature Range: Spirulina grows best between 30–35°C. Climate should be semi-arid to tropical. Avoid regions with frost or with average temperature above 45°C.

Land Area Requirement

For medium to large-scale production, 3 acre of land is sufficient to support up to 20 raceway ponds along with auxiliary infrastructure like a harvesting unit, drying area, packaging room, storage, and a small on-site testing laboratory.

Step 2: Pond Construction

Raceway Pond Design

- Material: Construct ponds using reinforced cement concrete (RCC) or food-grade HDPE lining. Always use SS 316-grade material where metal contact is involved to avoid leaching.

- Design Specs: Typical pond dimensions are 100m length x 10m width x 0.4m depth. Ponds must have sloped bottoms for easier biomass collection.

- Agitation: Paddle wheels ensure continuous culture movement, improving oxygenation and nutrient distribution.

pH and Water Control

- Spirulina thrives in an alkaline environment. Use sodium bicarbonate to maintain a pH level of 9–11.

- CO₂ naturally dissolves from the atmosphere, aiding in photosynthesis. However, some farms also inject CO₂ to speed up growth under controlled monitoring.

Step 3: Spirulina Culture & Growth Medium

Spirulina Starter Culture

Always start with a certified, contamination-free spirulina culture obtained from authorized research labs or organic-certified farms. Initial inoculation volume should be 10% of pond volume to ensure dominance over contaminants.

Nutrient Composition

- Carbon Source: Sodium bicarbonate is crucial for growth and must be dosed according to pH trends. Organic sources of carbon such as sugars and other dissolvable plants material can be used.

- Nitrogen: Use OMRI-approved nitrogen sources like nitrate-based fertilizers or organic fertilisers.

- Phosphates & Minerals: Add potassium phosphate, magnesium sulfate, iron sulfate, zinc, and selenium in specific proportions if doing it inorganically Organically you can use phosphate rock, minerals and source organic nutrients.

Ideal C:N:P Ratio

The recommended C:N:P ratio of 24:14:1 ensures high growth rate and maximum protein synthesis. Adjust nutrients weekly based on lab analysis of culture density and purity.

Step 4: Monitoring & Automation

Large-scale spirulina production is impossible without automation. Manual intervention leads to loss in quality, contamination and unreliable yield. You will also need multiple labor that adds labor cost, management issues that will make it non profitable.

IoT-Driven Automation Tools:

- Sensor Units: Continuously measure water pH, temperature, dissolved oxygen, and light penetration.

- Automated Nutrient Dosing Systems: Ensure balanced growth and avoid overfeeding which can trigger contamination.

- Remote Monitoring & Alerts: Receive real-time updates on mobile devices or SCADA dashboards.

- Data Logging: Tracks batch history, vital for certification and auditing.

Note: For a deeper dive into automation systems, check Automation in Spirulina Farming.

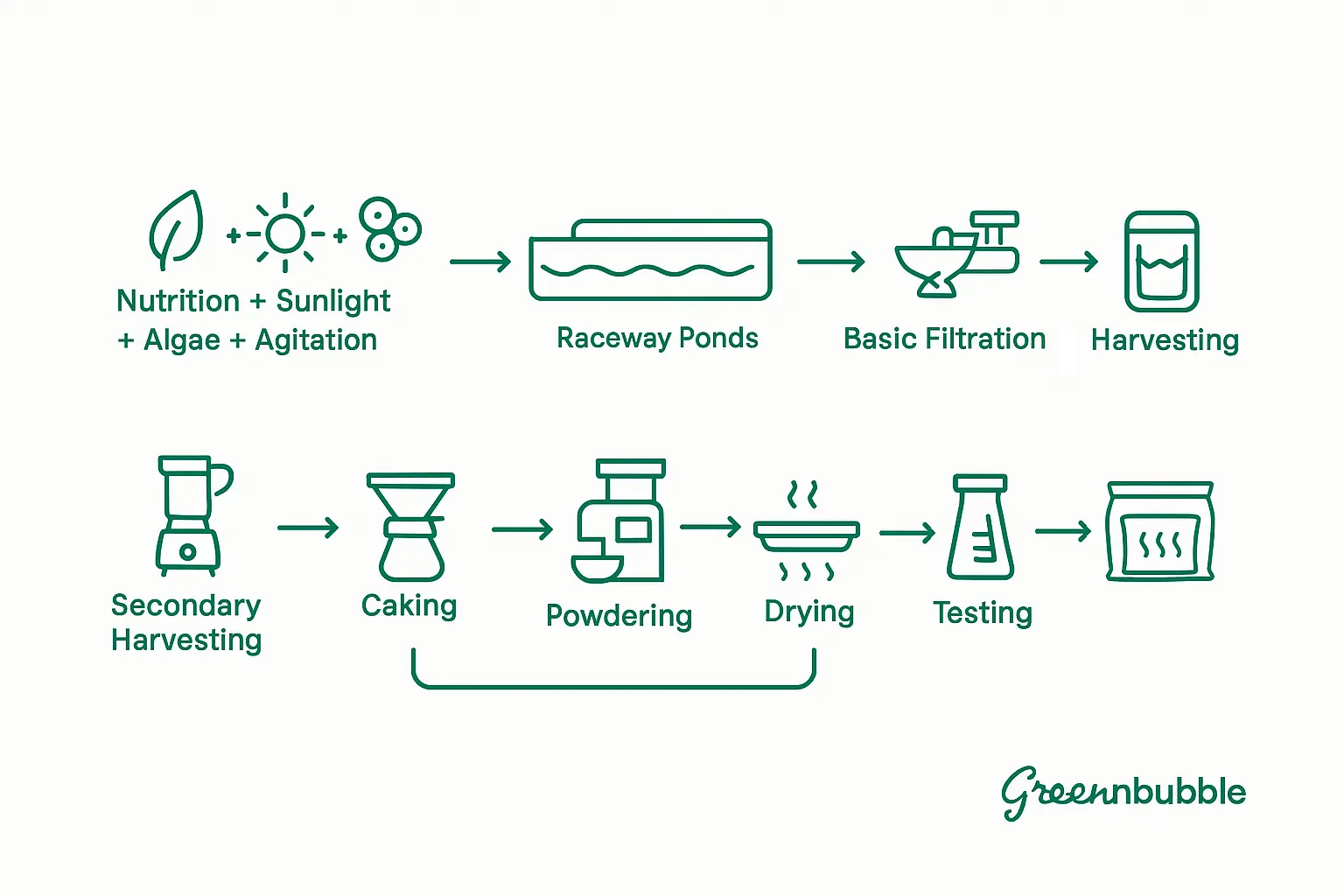

Step 5: Harvesting Process

Filtration & Dewatering

- Fine Mesh Filters: Use 500-mesh or finer nylon screens to collect spirulina biomass without losing the live culture. It’s best to use automated harvesting equipment like rotary drum filters by Greenbubble in case of commercial farms.

- Batch Harvesting: Begin harvesting spirulina after 10–14 days of culture initiation, then continue every 1–3 days depending on growth rate.

Hygiene & Contamination Prevention

- Install insect-proof netting and wind barriers around the pond.

- Harvesting should occur in a -closed clean room.

- Workers must wear gloves, hairnets, and follow HACCP protocols.

Step 6: Drying & Processing

Drying Spirulina

- Preferred Methods: Refractive Window Drying (RWD) and Vacuum Drying preserve heat-sensitive compounds like phycocyanin.

- Avoid: Sun drying or direct hot-air dryers that exceed 60°C, as these damage nutrients and reduce market value. Sun drying also takes long time that degrades nutrients and is not reliable being dependent on weather.

Grinding & Powdering

- Use ball mills or air classifier mills under GMP conditions.

- Final spirulina powder is sieved (80-mesh) and should have uniform particle size and a pleasant oceanic odor.

Step 7: Quality Control & Certification

Laboratory Testing

Every batch must be tested for:

- Nutrient Content: Protein (>60%), Iron (>410 mg/kg), Carotenoids (>5500 mg/kg), phycocyanin > 15%

- Contaminants: Arsenic, Lead, Mercury, E. coli, Salmonella, mold

- Microbial Load: Total plate count and yeast/mold counts must be within prescribed food safety limits

Certifications

- USDA Organic: Requires detailed logs, input traceability, and annual audits

- GMP & HACCP: Necessary for processing and exporting

- COA (Certificate of Analysis) from a NABL-accredited lab and in house lab is mandatory for sales

Step 8: Packaging & Storage

Packaging

- Use aluminum-laminated, opaque, air-tight pouches or PET jars to package spirulina

- Must include batch ID, COA reference, nutritional table, expiry date, and organic seal (if applicable)

Storage

- Store in clean rooms under 25°C

Step 9: Cost & Capital Breakdown

Spirulina Farming Cost in India (1-Acre IoT-Enabled Setup)

| Component | Estimated Cost (INR) |

| Pond Construction (20 units) | 20–25 Lakhs |

| Automation & Sensors and harvesting equipment | 13–16 Lakhs |

| Drying & Grinding Equipment | 15–17 Lakhs |

| Packaging Unit | 2–3 Lakhs |

| Lab Setup & Testing | 8–9 Lakhs |

| Misc. & Compliance | 10–12 Lakhs |

| Total Setup Cost | ₹75–95 Lakhs |

Government Support

India offers government subsidy schemes for farmers under MIDH, SFAC, and PMFME schemes. These can reimburse up to 40% of capital expenditure if organic certification and hygiene protocols are strictly followed. Proper documentation, business plans, and production records are essential for approval.

Conclusion: Building a Sustainable Spirulina Business

Spirulina farming is not just an agricultural activity—it is a bio-industrial operation requiring precision, planning, and high standards. It offers massive potential in India and abroad, but only when executed with scientific practices and robust infrastructure. From setting up nutrient-rich raceway ponds and deploying automation to drying with low-heat technologies and securing organic certification, every step directly impacts ROI.

If you’re serious about entering this space, surround yourself with trained microbiologists, invest in IoT-enabled tools, and focus on compliance from day one. Learn more about the future of spirulina farming in India and upcoming innovations that can give your farm a global edge.

Ready to build your own certified, profitable spirulina farm? Contact us for expert guides, turnkey solutions, and farm planning support.