Exporting spirulina opens access to high-value markets and long-term profitability, but it’s not as simple as scaling your pond size. The global spirulina trade is highly regulated and quality-conscious. Countries like the US, Germany, France, Japan, Australia, and South Korea import only organically certified, low-contaminant, traceable spirulina—often from farms that are audited multiple times per year. That means Indian farms looking to export must be export-ready in infrastructure, quality assurance, and documentation.

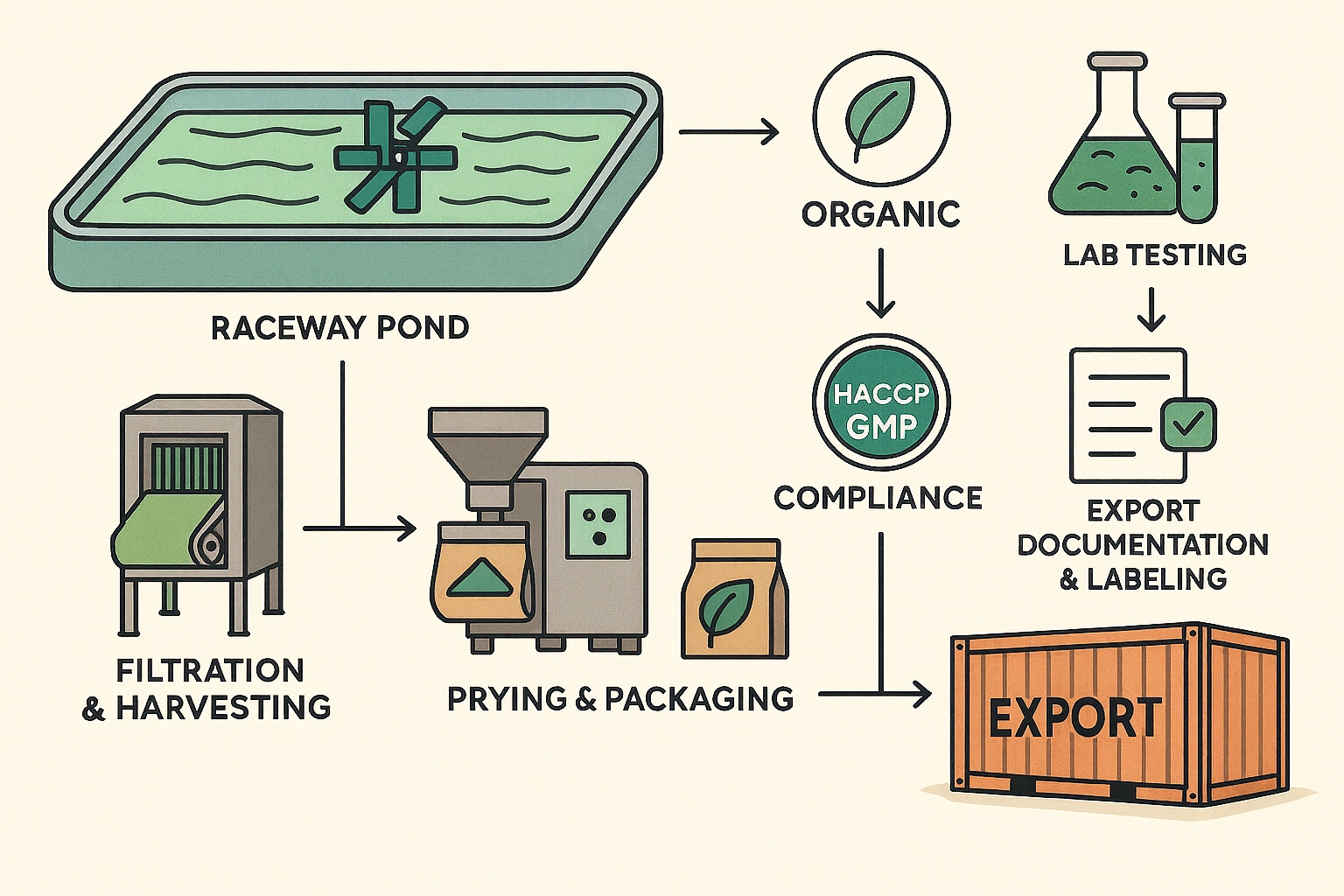

In this in-depth guide, we outline what it takes to make your spirulina farm export-ready: the essential machinery, certifications, SCADA-based traceability systems, packaging protocols, lab testing routines, and documentation practices that ensure smooth global distribution.

Why Export Markets Demand Higher Standards

Exporting spirulina is not just about production—it’s about meeting international expectations. Buyers across the globe are becoming more selective:

- Nutraceutical brands want consistent COA-verified quality

- Health supplement companies require GMP/HACCP facilities

- Consumers demand certified organic and traceable spirulina

This means:

- Batch-level traceability is now a baseline expectation

- Cleanroom packaging and low-heat drying are not optional – they’re essential

- Automated systems are increasingly necessary to meet consistency and compliance demands

Without robust systems in place, even high-quality spirulina may not clear customs or pass buyer audits.

Machinery Required for Export-Grade Spirulina Production

An export-ready spirulina farm is heavily reliant on specialized machinery to reduce manual error, ensure hygiene, and maintain nutrient integrity.

1. Raceway Ponds

- RCC or food-grade HDPE lined

- OMRI-compatible materials

- Must include slope and paddle-wheel agitation

- Designed for easy cleaning and total drainage

Regular inspection, automated pH monitoring, and contamination control (via mesh screening and controlled inlet flow) are key.

See raceway pond system options

2. Automated Harvesting System

Export-ready spirulina must be free from contamination and consistent in paste quality. This requires:

- 80-mesh filters prefilters

- 500 mesh drum filters

- Auto-dewatering ( vacuum or belt press)

- Stainless steel tanks

- SCADA-connected programmable valves

Fully enclosed systems minimize microbial load and support organic compliance.

Learn about automated harvesting equipment

3. Low-Heat Drying Equipment

Spirulina’s antioxidant value and color are destroyed at high temperatures.

Recommended dryers:

- Refractive Window Dryers (RWD): Low-temp and nutrient-protective

- Vacuum Dryers: More efficient for smaller volumes

Never use contaminating options like open air drying or solar drying very difficult to maintain certifications.

Compare spirulina drying systems

4. Grinding and Powdering Equipment

- SS 304/316 construction

- No plastic or aluminum contact

- Multiple mesh sieves for fine, uniform output

Sanitize equipment before every cycle. Use dedicated tools for organic vs non-organic batches.

5. Cleanroom Packaging Line

Packaging is the last point where quality can be compromised.

- Use HEPA-filtered, temperature-controlled rooms (<25°C)

- Nitrogen flushing for shelf life

- Tamper-proof, opaque, food-grade pouches or jars

- Labeling: batch no., expiry, QR-code, cert ID

6. SCADA System & Traceability Tools

Track everything from feed and inoculum to pH, drying curves, and packaging. Your SCADA system should:

- Enable real-time data logging

- Generate batch-wise traceability reports

- Integrate with lab test uploads and QR systems

Traceability not only helps with audits—it reassures buyers and builds brand trust.

Certifications Required for Spirulina Export

USDA Organic / EU Organic

- Must use OMRI-listed or EU-allowed inputs

- Require third-party audits, records of inputs, and full traceability

- Post-harvest facilities must be compliant with organic protocols

GMP Certification

- Necessary for nutraceutical buyers and export to North America

- Encompasses SOPs for hygiene, maintenance, record-keeping

- Requires cleaning schedules and facility design standards

HACCP Certification

- Ensures proactive control of food safety hazards

- Often required for exports to EU and Australia

- Needs hazard point documentation for raceways, harvesting, and drying

FSSAI License + APEDA Registration

- FSSAI is India’s domestic food safety license

- APEDA registration enables exporters to receive export codes and support

COA (Certificate of Analysis)

- Lab-certified batch-wise reports

- Mandatory for export

- Tests include:

- Phycocyanin content

- Protein concentration

- Microbial counts (TVC, yeast, mold)

- Heavy metal residues

Understand spirulina quality control standards

Common Export Challenges

1. Documentation Gaps

Missing or inconsistent records are the #1 reason for failed certifications and rejected shipments. Every batch must have:

- SCADA logs

- Lab reports (NABL-certified)

- Input material logs

- Storage records

2. Microbial Contamination & Shelf Life

Spirulina absorbs moisture easily. Even tiny lapses in drying or packaging can:

- Shorten shelf life

- Lead to bloating, odor, or disintegration

- Trigger customs rejections

Prevent with:

- Moisture meters

- Dry rooms

- Desiccants and airtight packaging

3. Certification Delays

Organic and GMP audits are time-consuming. Plan for:

- Initial inspection (1–2 months)

- Non-conformance corrections (2–3 months)

- Repeat inspections or surveillance audits

Pre-certification mock audits can reduce this timeline significantly.

4. Labeling and Compliance Errors

Incorrect cert logos, missing traceability info, or country-of-origin labeling errors can all result in delays.

Cost Breakdown for Export-Ready Setup (1-Acre Farm)

| Component | Estimated Cost (INR) |

| Raceway construction | ₹20–25 Lakhs |

| Harvesting automation | ₹12–15 Lakhs |

| Low-heat drying unit | ₹10–18 Lakhs |

| Cleanroom + packaging unit | ₹6–8 Lakhs |

| SCADA + ERP traceability | ₹3–5 Lakhs |

| Certification + audit support | ₹8–10 Lakhs |

| Total Investment | ₹60–80 Lakhs |

Add ₹5–10 lakhs for solar backup, third-party lab contracts, and export consultation if needed.

Best Practices for a Globally Compliant Spirulina Farm

- Establish a QA team responsible for logs, audits, and documentation

- Perform monthly microbial and heavy metal tests

- Conduct quarterly internal audits to simulate USDA/GMP review

- Maintain clear SOP manuals for every equipment and process

- Keep a digital logbook for all parameters and integrate with label generation

Export Labelling Requirements

Export labels must include:

- Organic certification logo + ID number

- Country of origin (e.g., Product of India)

- Batch number, expiry, manufacture date

- Nutritional profile

- COA QR code or web verification ID

Ensure barcode readability and label water resistance. Rejections due to minor label non-compliance are more common than you think.

Conclusion: Export Success Depends on Structure

Spirulina farming for export is as much about systems and compliance as it is about cultivation. If you want your product to be shelf-ready in the US, EU, or APAC regions, you need a combination of machinery, certifications, digital traceability, and documentation discipline.

The upfront cost may be significant, but it opens doors to high-margin markets, large institutional buyers, and long-term brand equity. If your goal is to scale globally, it starts with investing in the right farm systems and certifications.

Explore our machinery and turnkey systems to begin building your export-ready spirulina operation today.