Smart Water Strategies for Sustainable and Cost-Effective Spirulina Cultivation

Water is to spirulina what soil is to traditional crops. From nutrient delivery to temperature stability, water is at the core of every spirulina farming operation.

But here’s the catch: spirulina cultivation demands clean, mineral-rich, alkaline water—not just any water. And with climate change, groundwater depletion, and rising costs, smart water use has become a top priority for both commercial spirulina farms and eco-conscious agripreneurs.

Enter: Rainwater harvesting and water reuse—two strategies that are not just sustainable, but economically and operationally essential for long-term success.

In this blog, we’ll break down:

- Why water matters so much in spirulina farming

- How to harvest rainwater effectively

- Safe reuse strategies for spirulina water

- Systems, setup costs, and maintenance

- How this ties into organic certification, ROI, and future-ready farming

Let’s start with the basics.

Why Water Quality Is Critical in Spirulina Farming

Spirulina thrives in water that’s:

- Alkaline (pH 9–11)

- Warm (30–35°C)

- Free from heavy metals and pathogens

- Rich in carbon, nitrogen, phosphorus, and trace minerals

Unlike soil crops, where many contaminants are filtered out naturally, water-based farming needs constant vigilance to prevent:

- Culture collapse

- Contamination (bacterial, algal, or insect-borne)

- Certification failures (for organic or HACCP standards)

That’s why farmers can’t afford dirty, unstable, or fluctuating water supplies. Rainwater, when managed well, is a game-changer.

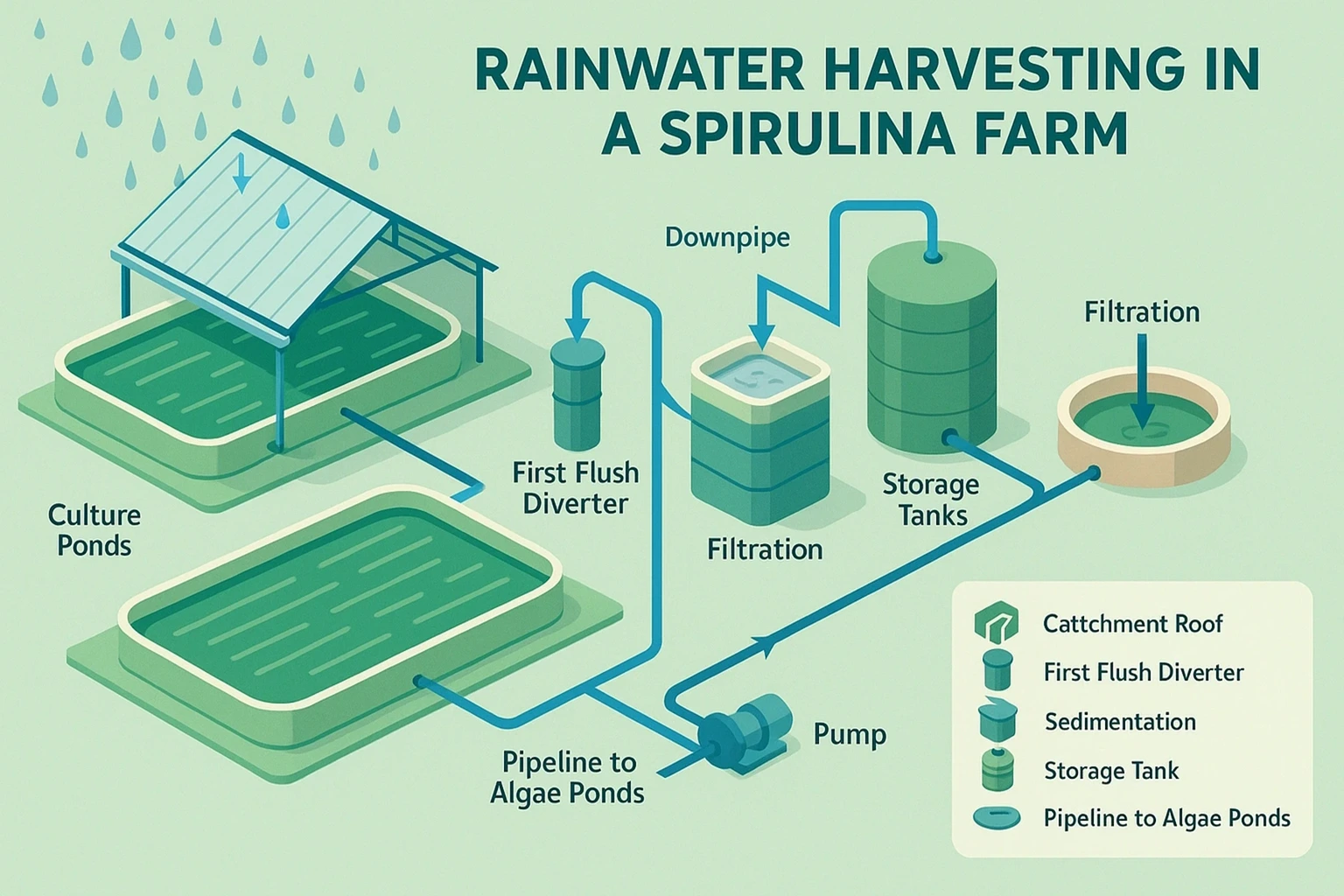

Rainwater Harvesting in Spirulina Farming

Rainwater harvesting is the collection and storage of runoff from rooftops or farm structures for later use. While this concept isn’t new, its application in spirulina farming is both strategic and practical.

Benefits of Using Rainwater:

- Naturally soft and free from salts

- Low total dissolved solids (TDS)

- Minimal microbial load (if stored correctly)

- Reduces borewell dependency

- Lowers water bills and pumping energy costs

Ideal Uses in a Spirulina Setup:

- Tank water replenishment

- Dilution during high evaporation seasons

- Washing and cleaning purposes

- Water for nutrient pre-mixing

🛠️ How to Set Up Rainwater Harvesting on a Spirulina Farm

Here’s a practical framework for setting up rainwater harvesting on a 1-acre spirulina farm:

1. Catchment Area

Use your shed roofs, lab rooftops, and greenhouse structures. These are ideal flat surfaces for collecting rain.

- A 100 sq. m roof can collect ~90,000 liters annually (in 900 mm rainfall zone)

2. Gutters and Filtration

Install:

- Sloped PVC gutters with mesh covers

- First flush diverters (to remove initial dirty rain)

- Gravel-sand-charcoal filter units or inline sediment filters

- Borewell recharge pits

3. Storage Tanks

Choose food-safe HDPE or RCC tanks:

- Primary: 1,00,000–3,00,000 liters

- Backup: Smaller tanks for separation, if needed

- Cover all tanks to prevent algal growth

4. Integration with Culture Tanks

- Use pH and TDS sensors to assess suitability before adding to spirulina tanks

- Most farms blend harvested rainwater with borewell water + nutrients after filtration

➡️ Want a ready-made system? Explore Spirulina Farming Turnkey Solutions

Water Reuse: Making Spirulina Farming Circular

After months of operation, spirulina tanks are partially drained. This leftover water—known as harvest return water—contains:

- Residual nutrients (carbonates, nitrates, phosphates)

- Some dead or broken spirulina cells

- Minimal live culture (if mesh is efficient)

Why Reuse It?

- Reduces nutrient wastage

- Lowers fresh water consumption by 30–40%

- Minimizes effluent discharge, easing compliance

However, reuse must be controlled to avoid:

- Contamination buildup

- Bacterial blooms

- Culture fatigue (from excessive reuse without dilution)

Safe Reuse Strategies: What to Test and Treat

Before reusing culture water, you need a basic farm lab and SOP for water quality.

Test Before Reuse:

| Parameter | Ideal Range |

| pH | 9.0 – 10.5 |

| TDS (Total Dissolved Solids) | < 2000 ppm |

| Ammonia | < 1 ppm |

| Nitrate/Nitrite | < 50 ppm |

| Pathogens | None detected |

Treatment Steps:

- UV or ozonation to reduce microbes

- Micro-filtration for dead biomass

- Dilution with fresh or rainwater

- Aeration to re-oxygenate and refresh

Most professional farms maintain a recycle ratio of:

1 part recycled water : 1–2 parts fresh or harvested rainwater

Bonus: Reusing Dryer Condensate & Washing Water

- Vacuum dryers often release condensate water as steam cools—this can be collected and used for:

- Floor cleaning

- RO pre-flushing

- Non-culture operations

- Harvest mesh wash water, when collected in tanks, can also be filtered and reused for non-sensitive cleaning activities.

- All filtrate from the machines can be sent back to the ponds.

Sustainability isn’t always about complexity—it’s about smart segregation and planning.

➡️ Learn how drying and equipment water management works: Spirulina Dryer Machine

Designing a Closed-Loop Water System for Spirulina Farming

The dream? A zero-discharge, closed-loop spirulina facility. With the right systems, this is absolutely achievable.

Sample Setup (for 1-acre farm):

- Rainwater harvesting unit (30,000L)

- RO or UV-treated borewell backup

- Harvest return tank (10,000L)

- Filter + blend tank for mixing rain and reuse water

- Sensor-controlled pumps for flow automation

- Overflow directed to vegetation zone

Result?

You reduce:

- Borewell dependence by 50–60%

- Water cost per kg of spirulina

- Risk of pathogen contamination in untreated supply

Cost of Setting Up Water Harvesting & Reuse Systems

| Component | Cost Range (INR) |

| Rooftop collection system | ₹30,000–50,000 |

| First flush + sediment filtration | ₹15,000–30,000 |

| Storage tanks (20,000–30,000L) | ₹60,000–1.2 lakh |

| Reuse treatment system (UV, filter) | ₹1.2–2 lakh |

| Monitoring + plumbing | ₹50,000–80,000 |

| Total Setup | ₹2.5–4.5 lakh |

This is a one-time investment that pays off in:

- Lower recurring water bills

- Improved compliance

- Sustainable branding (green label products)

Added Benefits for Organic & Export-Ready Farms

If you’re targeting:

- USDA Organic or EU Organic certification

- Export markets in EU, UAE, or North America

- HACCP, GMP, or ISO 22000 audits

Then water source and handling become critical checkpoints.

Certified farms must:

- Maintain records of water quality

- Document any reuse and treatment

- Avoid using contaminated or untreated water

Rainwater + treated reuse water = better control + lower risk

Expert Thoughts: Water Is the Hidden Backbone of Spirulina Success

You can have the best tanks, lab, or drying system—but if your water quality is poor or inconsistent, your culture will suffer, and your ROI will collapse.

Rainwater harvesting and water reuse aren’t just green slogans. They’re smart, profitable strategies to make spirulina farming resilient, cost-effective, and certification-ready.

From small pilot farms to 100-acre facilities, the best spirulina operations are those that think circular, not linear.

Ready to Build a Water-Efficient Spirulina Farm?

At Greenbubble, we design and implement turnkey spirulina farms that come with:

- Water harvesting layouts

- Reuse-compatible plumbing and filtration

- Sensor integration for water quality

- Organic and export-compliant protocols

Don’t just grow spirulina. Grow it smart.

👉 Contact us today for water-efficient farm designs, consulting, and equipment.