Scaling up spirulina farm from small-scale to mass commercial production comes with several challenges that, if not addressed, will hamper the sector’s growth. These challenges range from the labor-intensive processes of cultivation using traditional practices, to maintaining consistency in the products and their quality and complying with the higher international standards. Some of these barriers can be addressed, such as these include implementation of new technologies that promote labor productivity, compliance with international edible grocery safety, and quality control.

Challenges in Scaling Spirulina Farming

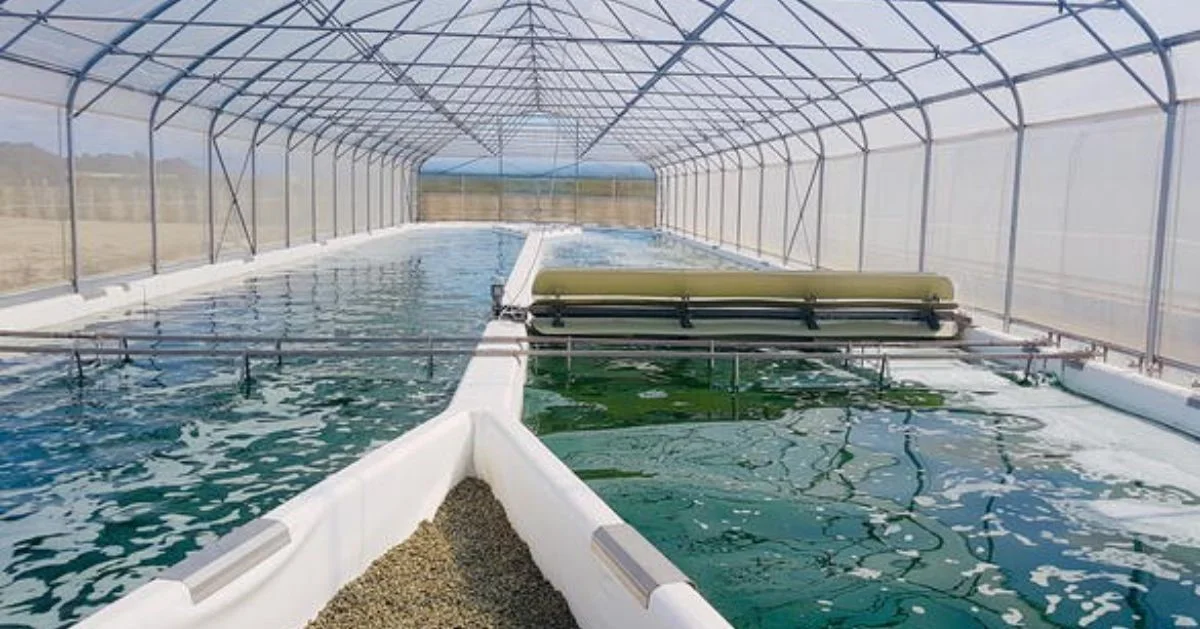

- Labor-Intensive Traditional Farming Methods – One of the most important issues regarding the production of spirulina on a large scale is how labor-intensive the process of production through traditional farming methods is. As it occurs in nature, spirulina grows in shallow ponds and its cultivation, harvest, and post-harvest processing are very often low mechanized and mostly manual. Heavy reliance on manual labor can give rise to inefficiency since the process is tedious and hampers mass production. Workers have to carefully watch algae as they grow, harvest it by hand, and often dry it using primitive methods thus making mass production impossible.

- Contamination Risks – Being an actively sensitive organism, spirulina has environmental requirements that need to be met for it to grow successfully. One of the greatest problems when mass-producing is the threat of other algal species, bacteria, or heavy metals which tend to lower the original product’s quality and safety. The open pond systems customarily employed in the cultivation of spirulina are having a high propensity for contamination as the environment is exposed which leads to uncontrolled conditions.

- Inconsistent Quality – Another bottleneck while expanding the scope of spirulina cultivation is ensuring quality control. There are several factors that affect the quality of spirulina including the water conditions during growth and the methods of harvesting and processing. Water quality, temperatures, or quite simply, sunshine amount leads to varying end products about nutrients, colors, and tastes.

- Compliance with International Standards – Spirulina sells across the world. Every region or country has its unique standards, rules, and regulations concerning the manufacturing and marketing of foodstuffs. Farmers growing spirulina to enhance the exportable products must conform to Good Manufacturing Practices (GMP), Hazard Analysis and Critical Control Points (HACCP), or other related international food safety norms. In this regard, these standards guarantee that the spirulina which is produced does not have any health hazards and is uncontaminated.

Yet, these international requirements can be an elaborate and expensive affair for farmers. Building the relevant infrastructure, training people, and acquiring the relevant certifications requires a hefty sum and may prove to be a barrier to small-scale farmers aiming to venture into wider markets.

Solutions to Overcome Challenges in Scaling Spirulina Farming

- Adopting Advanced Technology – Changing the traditional methods of spirulina farming which are labor-intensive today, will need the incorporation of modern technology. This will mitigate the costs of labor and allow for increased production and maintained quality through mechanized harvesting methods and improved drying technologies. With more technology in farming, farmers can upscale their businesses while maintaining quality and markedly cutting down the costs of production. Increased efficiency of spirulina farming operations not only puts it at an upper hand over its competitors but also makes it more scalable.

- Implementing GMP and HACCP Standards – Moving towards the HACCP System Incorporating GMP and HACCP standards is one of the most efficient ways to achieve international standard compliance. Through GHP these food safety management systems enable the farmer to pinpoint key risks or hazards through the farming practices and implement measures to avert such risks throughout the production cycle.

GMP ensures control of production in a clean surrounding while HACCP is concerned about tracing uncontaminated productions through critical control points. Adhering to these standard procedures can raise the level of safety and quality of the products for spirulina farmers ensuring that they effectively penetrate and stay in the international markets. - Using High-Quality Feed – The quality of spirulina is significantly determined by what nutrients the spirulina is given throughout the cold cultivation of the culture. This valuable product can be optimized by using high-quality feed that would ensure that the end product is enriched with some of the vital nutrients like protein vitamins and even minerals. The right type of feed does not only improve the quality of the finished spirulina but it also increases the speed of growth enabling farmers to boost production without affecting the quality.

- Employing Advanced Drying Techniques – The drying of spirulina is a very significant area for the maintenance of the quality and nutrient content of the end product. Older methods such as sun drying or solar drying are dependent and will often lead to the depletion of some of the key vitamins. To maintain the quality of the product both in appearance and essential nutrients farmers should use refractive window dryers, vacuum dryers, and other advanced drying techniques. Low-temperature-drying methods make it possible to preserve the nutrients of spirulina and keep the risk of its oxidation and contamination to the lowest level. Implementation of such practices enables farmers to comply with the stringent quality requirements of international markets more easily.

- Consulting with Industry Experts – Engaging industry experts on the issues of spirulina farming for mass-scale production is important due to its specificity which is the integration of agricultural technology with food safety and market forces. Farmers need to involve competent experts who understand the best practices, appropriate technologies, and current policies. These specialists assist in the implementation of the necessary processes for the expansion of the operations, maximization of farmer’s efficiency, and global compliance.

Conclusion

Greenbubble Spirulina Farming Solution has developed detailed consulting services to assist the spirulina production farmers in each process of production. Farmers receive assistance in the fields of technology, quality, and international standard compliance enabling them to expand their production capabilities. The solutions offered by Greenbubble Algalworks Pvt Ltd make the process of scaling easier and more environmentally friendly. To learn how Greenbubble Algalworks Pvt Ltd can help you with your spirulina farming business, please visit https://www.spirulinafarming.com/