Advanced Dewatering That Thinks for Itself

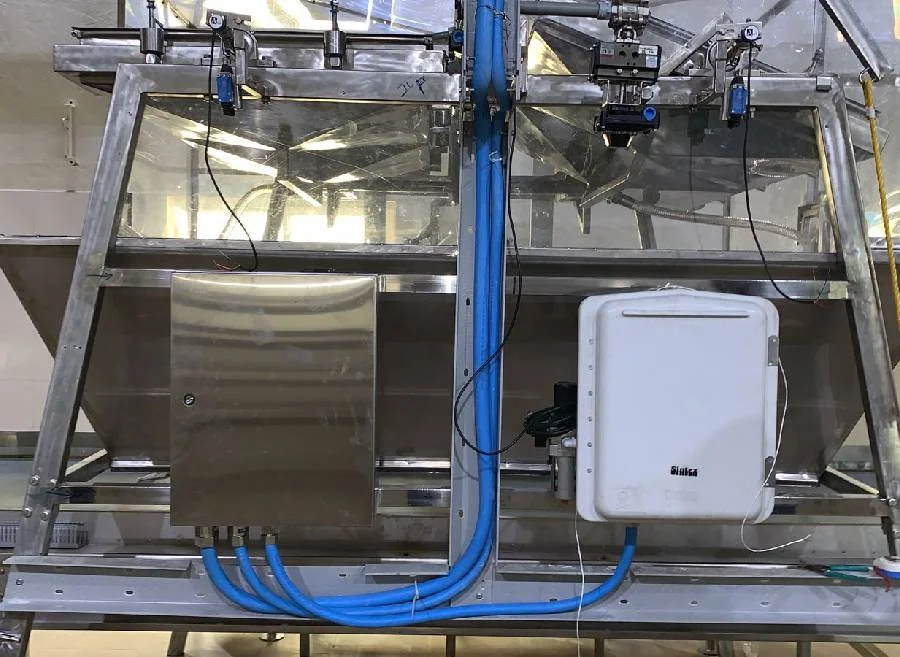

Our Auto Discharge Spirulina Dewatering System redefines post-harvest moisture control. Unlike traditional setups that require manual handling, this system utilizes negative pressure to extract water gently while achieving solid content levels up to 22%. What sets it apart is its smart discharge mechanism—it automatically offloads the spirulina cake into your designated dryer, vessel, or extruder without human intervention. This means lower labor costs, faster cycle times, and a more consistent dewatering outcome.

Its fully automated operation manages everything from vacuum levels to discharge timing—giving you a hands-free solution built for scale. Whether you’re a mid-sized grower or running a large-scale operation, this system brings industrial-level efficiency to your spirulina processing.

Built to Reduce Workload and Maximize Output

Spirulina farming demands both speed and care—especially at the dewatering stage. Our system addresses both. With automatic regulation of cycle parameters like vacuum intensity, batch timing, and discharge triggers, the entire process becomes predictable and repeatable. This consistency is key to producing high-quality spirulina at scale.

Why Automation Wins

Traditional dewatering systems come with limitations—manual errors, slower transitions, inconsistent discharge. The Auto Discharge upgrade removes these variables by automating critical points in the process. From auto-cake discharge into the next system to real-time pressure regulation, it enables a new level of efficiency. Designed for seamless integration with spray dryers, vacuum dryers, or custom setups, it makes scaling easier and smarter.

Auto Discharge,

Zero Hassle Dewatering

Smart Vacuum Control

Auto-adjusts pressure for optimal dewatering.

22% Solid Output

Achieves higher cake density in less time.

Auto Discharge Mechanism

No manual transfer—less contamination, faster workflow.

Fully Automated Cycle

Set parameters once and let the system handle the rest.

Integration-Ready

Works with your dryers, extruders, or vessels out-of-the-box.

Dewatering isn’t just a technical process—it’s the moment your spirulina production can gain or lose efficiency. At Greenbubble, we’ve engineered a smarter way forward. Our Auto Discharge Spirulina Dewatering System eliminates bottlenecks and manual errors while improving quality and reducing operational costs. From the moment the slurry enters to the point it’s ready for drying, every step is optimized for purity and speed.

If you’re aiming for consistent yields, lower workforce dependency, and tighter quality control, this is the upgrade your farm needs. Our system is already trusted by modern spirulina farms across India and beyond.

Let’s make your farm smarter.

Get in touch today to schedule a demo or consultation—let’s elevate your spirulina processing together.

Spirulina Farming FAQs

Everything You Need to Know About Commercial Spirulina Farming – From Setup to Profitability!

Following parameters need to be met while selecting land to set up a plant.

- low cyclone area

- flat land

- road approach

- less rainfall

- no hills or mountain shadow

- high temperature and dry land

- Mild or higher temperatures in winters

- water source (preferably ground water)

- Spirulina usually grows in hot & extremophile conditions and can sustain very high temperatures

Land Selection Criteria for a Spirulina Production Plant [Detailed Version]

1. Climate & Location Suitability

| Parameter | Requirement | Why It Matters |

|---|---|---|

| Cyclone / Wind Risk | Low-risk zone | Protects ponds, sheds, power lines, and prevents operational disruptions |

| Rainfall & Humidity | Low rainfall, low humidity (dry regions preferred) | Reduces pond dilution/overflow risk and lowers drying energy load |

| Sunlight Availability | High sunlight, minimal cloud cover | Directly improves Spirulina productivity and growth consistency |

| Shadow-Free Area | No hills, mountains, or tall obstructions | Prevents sunlight blockage and uneven pond temperatures |

| Temperature Profile | Warm-to-hot summers, mild winters | Enables stable year-round production with minimal winter downtime |

2. Topography & Civil Suitability

| Parameter | Requirement | Why It Matters |

|---|---|---|

| Land Gradient | Flat land | Minimizes earthwork and ensures uniform pond depth |

| Flood Risk | Non-flooding plot with natural drainage | Prevents contamination and structural damage |

| Drainage Control | Ability to divert rainwater/runoff | Protects ponds from overflow and culture loss |

| Soil Bearing Capacity | Good bearing capacity, low settlement risk | Avoids pond deformation and liner damage over time |

3. Water Availability & Quality

| Parameter | Requirement | Why It Matters |

|---|---|---|

| Water Source | Assured year-round supply (preferably groundwater) | Ensures uninterrupted production cycles |

| Borewell Yield | Adequate and sustainable discharge | Supports scale-up and continuous operations |

| Mandatory Water Tests | pH, TDS, hardness/alkalinity, iron, manganese | Ensures culture stability and process efficiency |

| Heavy Metal Testing | Mandatory (especially for export) | Critical for food-grade and international compliance |

| Legal Permissions | Groundwater extraction permissions checked | Avoids regulatory issues and shutdown risks |

4. Access & Utilities

| Parameter | Requirement | Why It Matters |

|---|---|---|

| Road Access | All-weather motorable road | Smooth movement of machinery, inputs, and dispatch |

| Electricity Supply | Reliable grid power | Essential for aeration, pumps, dryers, and lighting |

| Backup Options | Space for DG set / solar | Ensures power continuity during outages |

| Telecom & Internet | Stable mobile and data connectivity | Required for monitoring, CCTV, automation, and reporting |

5. Contamination Risk & Compliance Readiness

| Parameter | Requirement | Why It Matters |

|---|---|---|

| Industrial Distance | Far from factories, quarries, dumping yards | Prevents air and water contamination |

| Sewage & Effluents | No nearby sewage channels or drains | Eliminates biological and chemical contamination risk |

| Pesticide Drift | Avoid high pesticide-use agricultural zones | Important for premium, organic, and export markets |

| Land Title & Legal | Clear ownership and approval feasibility | Smooth project execution and financing |

| Expansion Potential | Scope for future expansion | Spirulina operations benefit significantly from scale |

Both Central & State Governments have multiple schemes and subsidies depending on the zone or region where the project will be built. These schemes are available with capital subsidy incentive, interest subsidy incentive and as financing schemes – subject to availability based on the applicant’s profile, state & Region.

Yes, the demand for spirulina in India is rising due to its superfood status and benefits like high protein (60%+), antioxidants, balanced amino acid profile and essential vitamins. The nutraceutical, pigment industries and cosmetic industries drive the bulk demand, with additional interest from the animal feed, aquaculture sectors and bio fertilizers. Health-conscious consumers are increasingly seeking organic spirulina, making certified farms more competitive. However, export markets (EU, USA) offer higher profit margins and volumes because of higher consumption and awareness in their respective countries.

Spirulina quality is assessed in laboratories for key parameters like protein content (≥60%), phycocyanin levels (≥15%), heavy metals (lead, mercury, arsenic), microbial contamination, and purity. The Certificate of Analysis (COA) from third-party labs ensures compliance with global standards like USDA Organic, EU Organic, GMP, and HACCP. A simple at-home test includes checking colour (deep green-blue) and smell (fresh, non-fishy). For commercial-grade quality assurance, regular lab testing and batch tracking are essential.

Spirulina is relatively easy to cultivate under the right conditions, but maintaining high quality can be challenging. It thrives in high-pH, mineral-rich water with consistent agitation and ample sunlight. However, farms must closely monitor for contamination—such as heavy metals, harmful bacteria, and cross-contamination with other algae. Maintaining an optimal pH level (between 9 and 11) and using controlled drying methods are essential to preserve its nutritional value. Scaling up production requires automation of processes like filtration, harvesting, drying, and packaging, making commercial farming significantly more complex than small-scale setups.

Yes, India exports spirulina, but it requires strict regulatory compliance. To export, farms must obtain FSSAI, USDA Organic, and EU Organic certifications, ensuring compliance with global quality standards. Countries like the USA, EU, and Japan demand batch tracking, third-party lab testing (COA), and HACCP/GMP practices to verify purity. Organic-certified spirulina fetches higher prices, but maintaining consistent quality, low contamination levels, and proper documentation is crucial for global acceptance.

The ideal tank size for spirulina farming depends on production goals. Small-scale hobby farms can start with 1,000-5,000 litres (10-50 sq. m. tanks), while commercial farms require multiple tanks ranging from 4lakh to 8lakh litres for viability and to meet market demand. Tanks should be food-grade, contamination-free, and have an efficient agitation system to ensure even nutrient distribution. The depth should be around 20-30 cm, allowing optimal light penetration for photosynthesis. Regular pH, temperature, and contamination checks are crucial for consistent yields.

There are multiple Spirulina species, and the best one depends on the intended use. Arthrospira platensis is widely used due to its high protein content (60–70%), β-carotene, and phycocyanin levels. It is also GRAS-approved by the FDA, which makes it easier to market and sell. When choosing Spirulina, opt for organic-certified, lab-tested products with high phycocyanin content (≥15%) for the best health benefits. Low-quality, mass-produced Spirulina may contain toxins, heavy metals, or reduced nutrient levels. Therefore, selecting products that come with a valid Certificate of Analysis (COA) is essential.

Spirulina is expensive due to its high-quality control standards and nutrient-rich composition. Factors like pH balance, controlled agitation, organic compliance, and industrial nutrition preserving dryers increase production costs. Organic-certified spirulina requires third-party testing (HACCP, GMP, USDA Organic) for contaminants like heavy metals and bacteria, adding to expenses. Additionally, import restrictions and packaging for nutrient retention contribute to the high pricing. Despite the cost, its superior nutritional profile and increasing demand justify the premium.

Countries like the Japan, Thailand, and China lead in commercial spirulina production. France and Germany also produce premium-grade spirulina in small scales, often cultivated in controlled greenhouse environments. Indian spirulina has strong potential, but farms must focus on organic certification and contamination-free production to compete with global suppliers.

To start a spirulina farm, you need a warm climate (25-50°C), Fresh potable water and a contamination-free environment. Begin by setting up growth tanks (preferably food-grade material), an agitation system, and an organic nutrient supply. Ensure regular water testing, lab analysis for purity, and compliance with organic standards for targeting premium markets. Drying and packaging should use low-heat methods to retain nutrients. Marketing strategies should focus on B2B (nutraceuticals, pigment, cosmetics) and direct-to-consumer (powders, tablets, supplements). Hiring consultants can help you cover all bases and avoid costly mistakes during setup and operation.

The cost of starting a spirulina farm varies based on scale and automation level. A small-scale Hobby farm (1,000 sq. ft.) may cost around ₹5-10 lakh, while a commercial setup can exceed ₹1CR due to expenses like land preparation, building costs, Machineries, Raceway tanks construction, agitation systems, working capital, electrical and plumbing, lab setup many other management and administrative expenses. Key costs include Civil works, harvesting, drying system (Industrial nutrition preserving dryers), certification expenses (like FSSAI, USDA Organic, EUO, ECOCERT, HACCP, GMP) and working capital. While initial investment is high, proper planning, market positioning and quality assurance can yield significant returns.

Spirulina farming can be highly profitable, but success depends on factors like production scale, automation, organic certification, Quality and market demand. While some claim an ROI of 300% within months, realistic profitability takes 2-3 years due to high setup costs for infrastructure to reduce labour dependency, increased up time and meet the quality standards. Organic-certified spirulina fetches premium prices in domestic and international markets, making it a viable long-term investment. However, strict quality control, regulatory compliance, and a reliable distribution network are key to ensuring consistent profitability.

Related Services

Let us help you