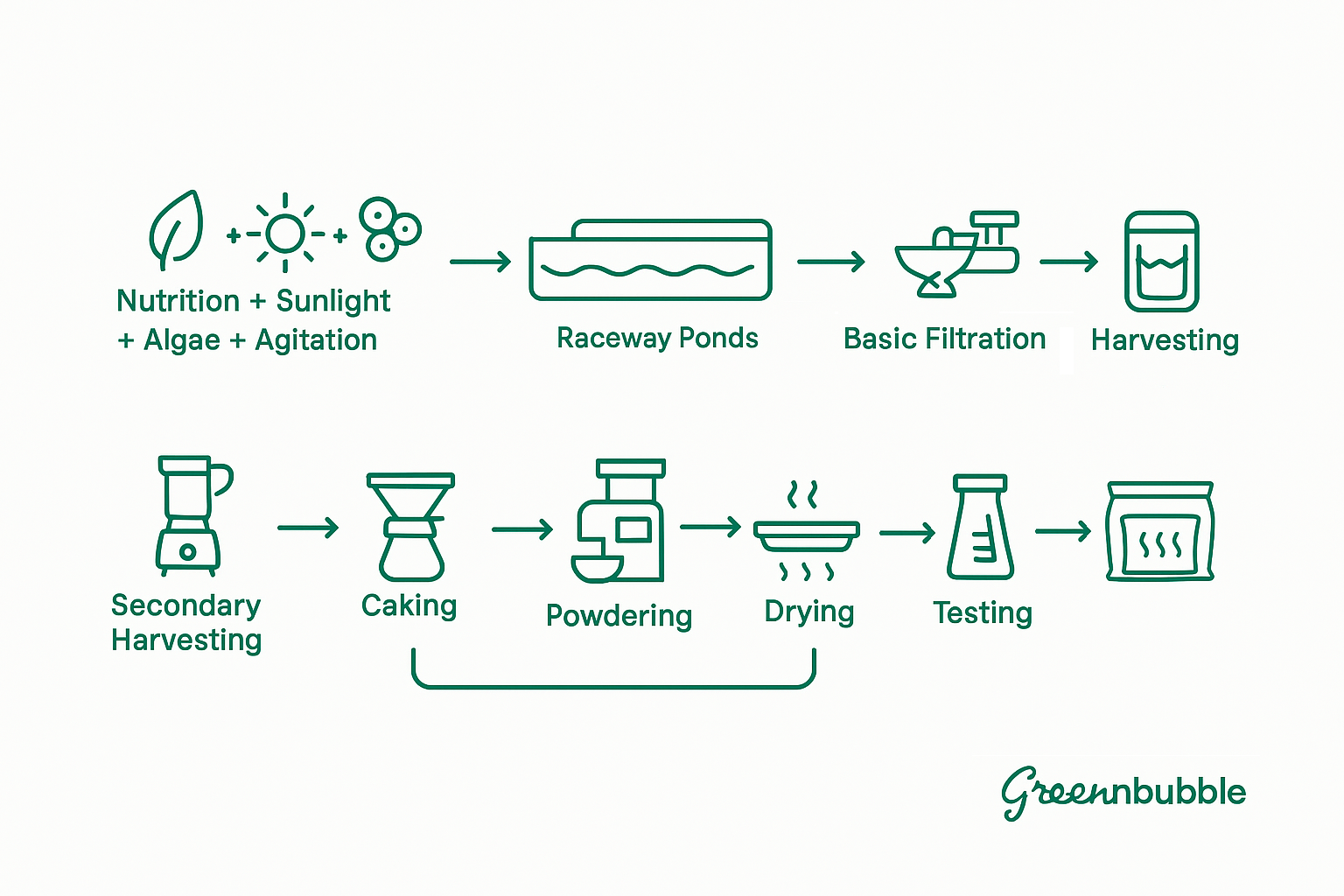

Producing high-quality spirulina powder involves far more than just growing algae. The journey from culture to powder is a carefully controlled, multi-stage process that determines the nutritional quality, purity, and market readiness of the final product. Each stage-from raceway pond cultivation to filtration, drying, and packaging-has a critical role in shaping product standards, especially for farms targeting organic or export-grade certification.

In this guide, we’ll walk you through every stage of spirulina production-from live culture management to shelf-ready spirulina powder. The process demands scientific knowledge, operational hygiene, proper documentation, and the right equipment to avoid quality loss or contamination.

Stage 1: Starting with Mother Culture

Every batch of spirulina begins with a healthy mother culture. This seed culture is maintained in smaller, enclosed tanks with precise control over:

- Temperature and pH

- Sterile feed addition

- Regular OD and microscopy checks

- Contamination prevention (no cross-use of tools)

A strong mother culture ensures a consistent inoculation base for all downstream raceways. Farms aiming for USDA Organic certification must also document feed input logs and avoid cross-contamination with other algae strains. Mother culture tanks are typically set up indoors to avoid exposure to pests and dust.

Stage 2: Raceways and Mass Cultivation

Once the mother culture is ready, it’s transferred to larger raceway ponds. These shallow, paddlewheel-driven ponds offer ideal light and nutrient conditions. Culture expansion in raceways is monitored using:

- Optical Density (OD) readings

- pH and temperature tracking

- Visual checks for bubble consistency, color, and smell

Raceways are designed to promote uniform mixing and light exposure. Organic farms typically maintain a C:N:P ratio of 24:14:1 using OMRI-listed inputs. IoT-enabled raceways use SCADA systems to monitor water levels, pH drift, and temperature spikes-enabling early warnings in case of infection or imbalance.

Well-managed raceways prevent contamination and enable fast biomass growth. Learn more in our raceway pond design guide.

Stage 3: Harvesting the Biomass

When the spirulina reaches harvestable OD levels, the biomass is pumped through filtration units:

- Clean water is returned to the pond (minimizing waste)

- Biomass is collected in food-grade containers

Harvest must be done early morning (ideally) or late afternoon to avoid heat stress, using automated rotary drum filters with fine 500-mesh screens, constructed from SS 316-grade stainless steel. Farms looking to automate this stage can benefit from automation and SCADA systems that monitor optimal harvesting windows and control pump operation. Harvesters should wear gloves, face masks, and sanitized footwear to avoid introducing bacteria or spores. Farms producing for capsules or export-grade powder often employ closed-loop filtration with minimal human contact.

Stage 4: Dewatering and Thickening

The wet spirulina contains 85–90% water. It must be dewatered using Vacuum filtration (recommended) or belt-press units or centrifuge units (optional) for faster operations, ensuring minimal shear stress to maintain cell integrity.

This stage yields a dense spirulina paste. Hygienic transfer and food-grade tools are essential to prevent microbial contamination. Stainless steel trolleys, airtight transport containers, and positive-pressure rooms can help maintain hygiene during transfer.

Farms operating under GMP standards must maintain logs of dewatering cycles and cleaning of mesh surfaces. Any visible change in paste color or odor must trigger batch hold protocols.

Stage 5: Low-Heat Drying

Drying is the most crucial stage for nutrient preservation. Spirulina must be dried below 42–45°C to retain:

- Phycocyanin (blue pigment)

- β-carotene and antioxidants

- Protein structure (60%+ retention)

Preferred drying methods include:

Avoid spray drying for organic or premium markets-it uses high heat and damages nutrients. RWDs use refracted heat energy and preserve heat-sensitive compounds while vacuum dryers remove moisture under low pressure.

Smart farms track drying time per batch and moisture percentage post-drying. Too much drying can make the powder dusty and lose aroma, while under-drying invites fungal risk.

Stage 6: Milling and Powdering

The dried flakes are crushed into powder using SS 316-grade stainless steel ball mills or air classifier mills under GMP conditions, followed by sieving through an 80–100 mesh for uniform particle size.

Powder is sieved to uniform particle size (typically 80–100 microns) and immediately moved to airtight containers. Humidity-controlled rooms (below 45% RH) are preferred to avoid clumping.

Farms targeting bulk exports also test for particle uniformity, color grading (L* a* b*), and moisture content before sealing. All contact surfaces must be food-grade and cleaned between batches.

Stage 7: Lab Testing and COA Generation

Before packaging, each batch undergoes lab testing in an in-house lab (mandatory for certifications) or NABL-accredited lab for:

- Moisture, protein, and pigment content

- Microbial safety (E. coli, Salmonella, yeast, mold)

- Heavy metals (lead, arsenic, mercury)

Certified farms must generate a Certificate of Analysis (COA) batch-wise. COAs are mandatory for USDA Organic, EU Organic, and FSSAI compliance.

Test reports from NABL-accredited labs or in-house validated labs should be stored digitally for audit readiness. Learn how to set up your in-house spirulina lab.

Stage 8: Packaging for Shelf Life

Spirulina powder is packed using:

- Nitrogen-flushed, multi-layered pouches

- Light- and air-barrier laminates

- Zip-lock or heat-sealed closures, vacuum-sealed with nitrogen flushing to maintain freshness and extend shelf life.

Packaging must be done in a controlled environment to avoid moisture re-absorption. Best practice involves:

- Final moisture test before sealing (<5%)

- Oxygen absorbers for long shelf life

- Label compliance with local and international regulations

Labeling must include:

- Nutritional breakdown

- Batch number and COA reference

- FSSAI or USDA Organic seal

- Best before and manufacturing date

- Storage instructions

Beyond Powder: Value-Added Products

Once the spirulina powder is packed, it can be further processed into:

- Tablets (using cold compression)

- Capsules (vegan or gelatin)

- Health drink blends

- Ready-to-mix smoothies or protein bars

These product types require additional licensing and compliance documentation under FSSAI, US FDA, EFSA, or equivalent bodies, especially for export markets.

Conclusion: Spirulina’s Journey from Pond to Powder

Each step of spirulina production-from mother culture to powder-is vital to the end-product’s success. Quality farming, precise drying, and rigorous lab checks help ensure your spirulina is not just nutritious, but safe, organic-compliant, and marketable.

For farmers, the real challenge lies in maintaining consistency across batches, especially in tropical climates with seasonal shifts. From input traceability to humidity control, every aspect matters.

Looking to build a turnkey production line that meets all stages of this journey? Explore our spirulina turnkey solutions for integrated farming, lab, and packaging systems.